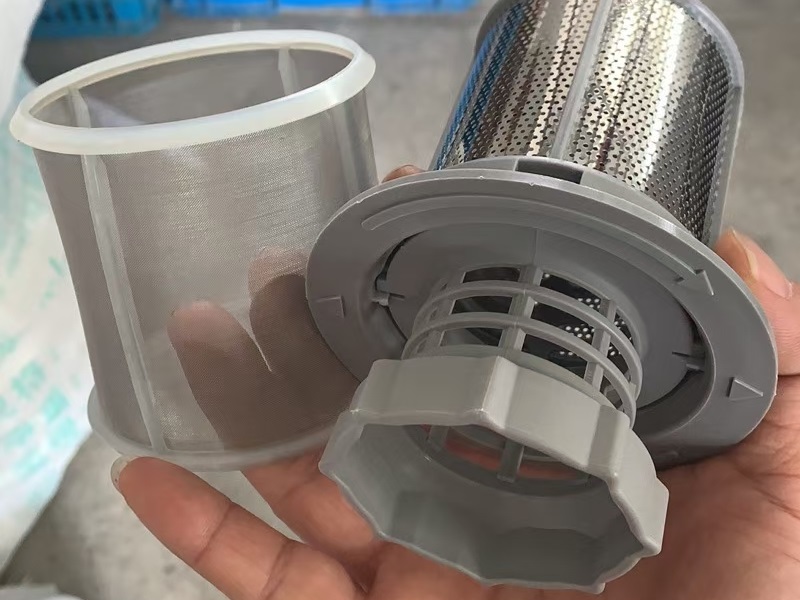

JD Hardware Wire Mesh Co., Ltd excels in over-molding and insert injection molding. We supply Injection Molding Filter Products, focusing primarily on developing in-line strainers, along with a diverse range of custom products. We adeptly combine forms such as cylinders or flat blanks with advanced materials like thermoplastics or thermoplastic elastomers (TPEs). This approach results in products that outperform traditional metal-mesh or welded designs.

Our process involves meticulously encasing prefabricated mesh within an injection mold, creating precise gaskets and robust support cages. We cater to a wide range of specifications, offering mesh sizes from a fine 10 microns up to a substantial 1500 microns. This flexibility allows us to address a spectrum of filtration needs.

At the heart of our operations is our team of experienced engineers, committed to crafting components that align seamlessly with client requirements. This client-centric approach ensures that each product we manufacture not only meets but exceeds functional expectations. JD Hardware Wire Mesh Co., Ltd blends technical expertise with innovative practices to deliver quality injection molding filter products suitable for a variety of applications.

Advantages of Insert Molding

- Improved Filter Performance: Our insert molding techniques enhance filter reliability by seamlessly integrating the mesh with the molded part.

- Comprehensive Engineering Expertise: Our team supports every step of filter development, from design to validation, accommodating both high and low volume production.

- Diverse Plastic Options: We offer a range of plastics including ABS, PP, PA66, AS, NYLON, and PET, catering to various application needs.

Variety in Mesh Selection for Injection Molding Filters

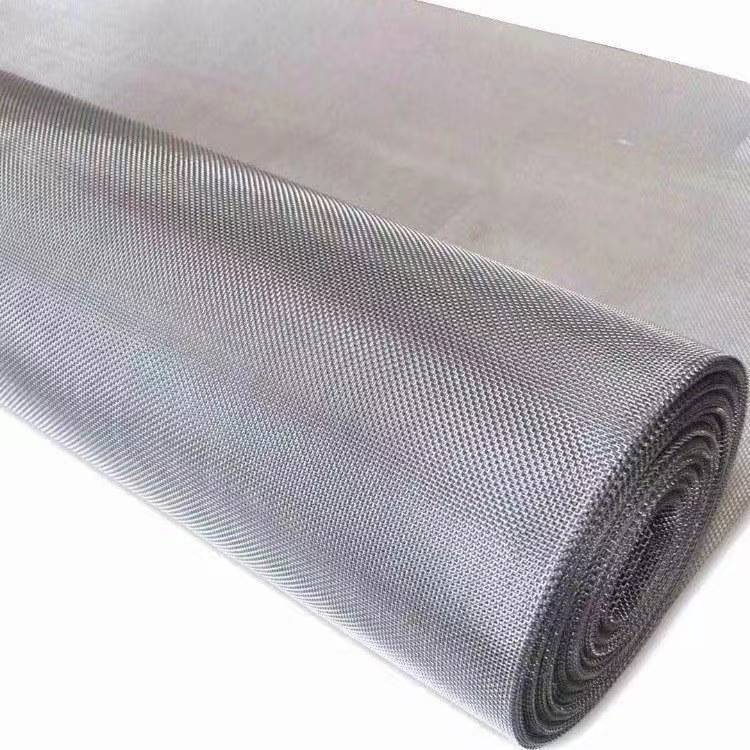

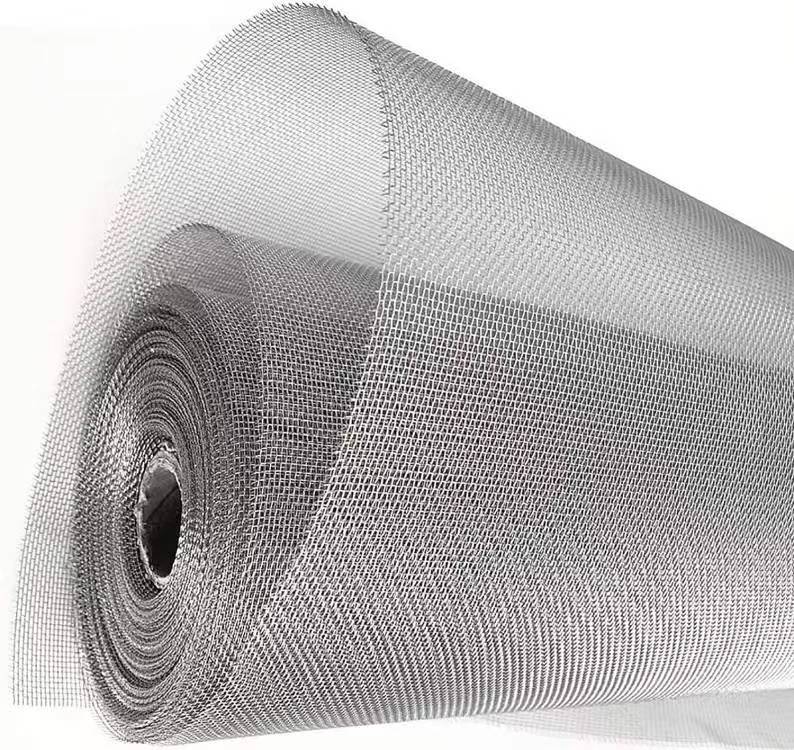

- Stainless Steel Filter Mesh: For durable and corrosion-resistant filtering needs.

- Brass Filter Mesh: Ideal for its malleability and rust resistance.

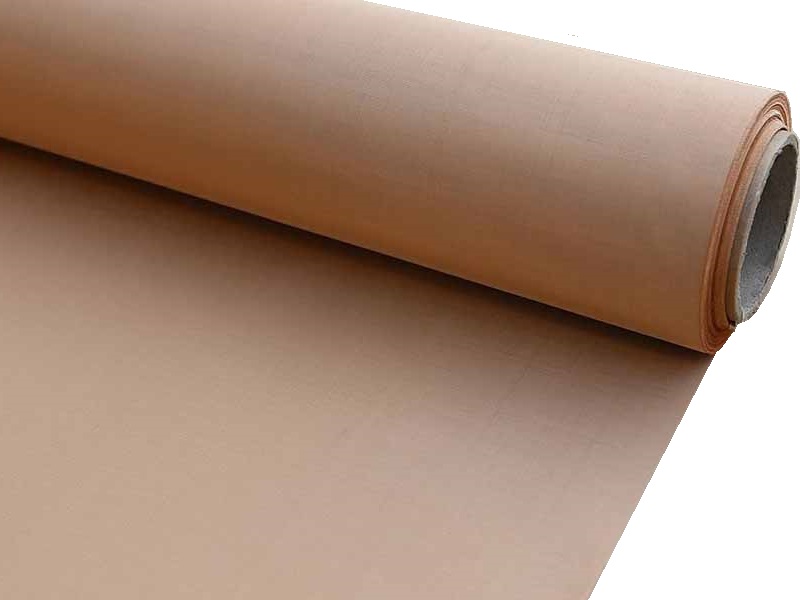

- Polyester Filter Mesh:Suitable for high-precision and chemical-resistant applications.

- Nylon Filter Mesh: Perfect for versatile filtering with excellent abrasion resistance.

- Polyethylene Filter Mesh: Great for its lightweight and cost-effective filtering capabilities.

General Specifications and Dimensions of Injection Molding Filters

- Mesh Material: Typically includes stainless steel, brass, polyester, nylon, and polyethylene, each offering different properties like corrosion resistance, flexibility, and chemical stability.

- Mesh Size: Ranges from very fine to coarse, often measured in microns. Fine meshes might start at 10 microns for precision filtering, while coarser meshes could go up to several hundred microns for more robust applications.

- Filter Dimensions: Common diameters range from a few millimeters for small applications to several centimeters for industrial use. Thickness and depth are also customizable based on requirements.

- Shape and Design: While cylindrical and disc shapes are standard, filters can be designed in various forms like domed, flat, or custom shapes to fit specific machinery or equipment.

- Durability and Strength: Factors such as material thickness, type of mesh, and construction method (e.g., over-molding or insert molding) contribute to the filter’s overall durability and strength.

- Temperature and Chemical Resistance: Depending on the material, filters can withstand different temperature ranges and chemical exposures, making them suitable for various industrial environments.

- Customization Options: JD hardware offer custom design and fabrication services to meet specific filtration requirements, including unique shapes, sizes, and material combinations.

Product Photo Showcase and Alias

Industrial Liquid Filters: Essential in various industries for purifying liquids, removing impurities to maintain process integrity.

Chemical Process Filters: Vital in chemical production, these filters separate impurities from chemicals, ensuring product purity and safety.

Pharmaceutical Filters: In drug manufacturing, these filters are crucial for removing contaminants, ensuring the purity of pharmaceutical products.

Automotive Injection Filters: Crucial for vehicles, ensuring clean air flow and optimal engine performance.

Medical Grade Filters: Essential in medical devices, maintaining sterility and preventing contamination in healthcare settings.

Water Treatment Filters: Used in water purification, crucial for removing contaminants to provide safe, clean water.

Food & Beverage Filters: Essential in food processing, they help in filtering particles from liquids, maintaining quality and safety.