JD Hardware Wire Mesh Co., Ltd specializes in producing and exporting Filter Caps, often known as binocular filters. Designed for use in high-viscosity melt filtration devices, these filters efficiently remove hard and condensed materials. Our Filter Caps are a vital component in the marine industry, especially for filtering in marine diesel engines, where their robust design ensures reliable performance under challenging conditions. Additionally, these caps are crucial in the chemical fiber industry for purifying spinning dope. They effectively eliminate impurities, thereby enhancing the quality of synthetic fibers and textiles. Their precise design is particularly suited for spinning nozzle applications, ensuring product purity and consistency.

JD Hardware Wire Mesh Co., Ltd is dedicated to providing high-quality Filter Caps that cater to the varied needs of our clients. Made with superior stainless steel sintering felt and stainless steel sintering wire mesh, these caps guarantee durability and effectiveness in a range of filtration applications, ensuring reliability and efficiency.

Common Sizes and Customization Capabilities

- Material Options: JD Hardware Wire Mesh Co., Ltd offers Filter Caps in a variety of materials to suit diverse filtration requirements. These include stainless steel wire meshes such as ss304, ss316, and ss316l, known for their durability and corrosion resistance. Brass wire mesh is also available, offering a unique combination of properties suitable for specific applications.

- Shape Customization:

Round Shape: Our round Filter Caps come in diameters ranging from 44mm to 600mm, accommodating a broad spectrum of applications.

Toroidal Shape: For toroidal-shaped caps, we offer inner diameters from 18mm to 250mm and outer diameters from 50mm to 350mm, ensuring a precise fit for specialized uses.

Rectangular Shape: Rectangular Filter Caps are available in widths from 50mm to 100mm and lengths from 60mm to 400mm, catering to various industrial needs.

Other Shapes: In addition to standard shapes, we also manufacture Filter Caps in square, oval, and other special shapes to meet unique requirements. - Mesh Weave Variations: Our Filter Caps can be manufactured with different mesh weaves to suit varying filtration levels. For plain and twill weaves, we offer options ranging from 8 to 80 mesh. For Dutch weaves, which provide finer filtration, our range extends from 12×64 mesh to 40×200 mesh.

- Customization Capabilities:JD Hardware Wire Mesh Co., Ltd’s customization capabilities in Filter Caps ensure that our products can meet the specific needs of our clients, whether they require standard sizes or bespoke designs.

Advantage

- Efficient Filtration and Durability: Designed for high-viscosity melt filtration, these caps effectively remove hard materials, ensuring purity and longevity in challenging environments.

- Versatile Industrial Use: Ideal for marine, chemical fiber, and synthetic fiber industries, they enhance the quality of the final product, especially in precision-critical applications.

- Easy Maintenance: The design facilitates simple cleaning and maintenance, reducing downtime and contributing to product quality in applications like textile spinning.

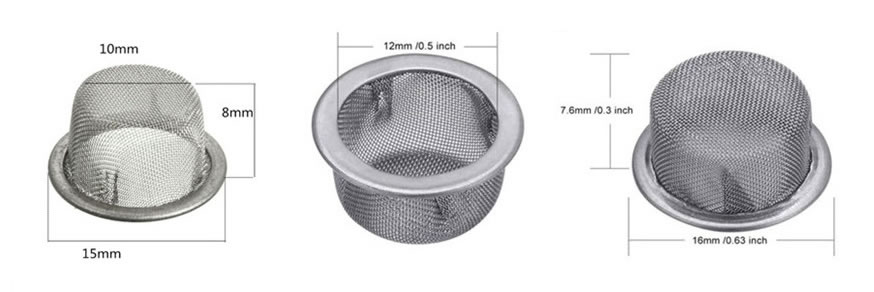

Product Photo Showcase and Alias

Filter Caps: Filter Caps are essential in high-viscosity melt filtration, efficiently removing hard and condensed materials, and are widely used in industries like marine and chemical fiber.

Binocular Filters: Binocular Filters, serving the same purpose as Filter Caps, specialize in purifying high-viscosity substances, ensuring the removal of solid impurities in various industrial processes.

Industrial Filter Covers: Industrial Filter Covers are used in heavy-duty applications to extract unwanted particles, ensuring the smooth operation of machinery in sectors like marine engineering and chemical processing.

Sintered Filter Caps: Sintered Filter Caps, known for their robust structure, are used in applications demanding high durability and efficient filtration, particularly in high-pressure environments.

Marine Filtration Caps are specialized for use in marine diesel engines, adept at purifying fuels and oils to ensure the efficient operation of marine equipment.

Chemical Fiber Filters are integral in the textile industry, especially in synthetic fiber production, where they ensure the removal of impurities from spinning dope.

Synthetic Fiber Caps are designed for the textile industry, particularly in filtering processes involved in synthetic fiber manufacturing, ensuring a high-quality end product.

Nozzle Filter Caps are essential in industries using spinning nozzles, where they maintain the purity of materials being processed, crucial for product consistency and quality.