JD Hardware Wire Mesh Co., Ltd specializes in the production of Test Sieve products, designed for precision and versatility. Our test sieves are indispensable tools primarily used in laboratories and quality inspection departments, excelling in tasks such as particle size analysis and scientific research. These sieves are not limited to professional use; they are also adaptable for everyday applications, efficiently sieving materials like coffee powder, grain, soil, and flour.

Understanding the diverse needs of our clients, we offer the ability to customize the aperture size of the mesh in our sieves. This flexibility ensures that each sieve can meet the exact requirements of different applications, whether for detailed scientific analysis or general use.

Categories

Our product line includes four key categories of test sieves to suit various needs:

- Common Test Sieves: Ideal for general sieving and sorting applications.

- Special Test Sieves: Tailored for specific, more demanding tasks.

- Laboratory Test Sieves: Perfect for detailed particle size analysis in laboratory settings.

- Sieve Shakers: Automated tools that enhance the efficiency and consistency of sieving processes.

Specifications and Customization of Test Sieves

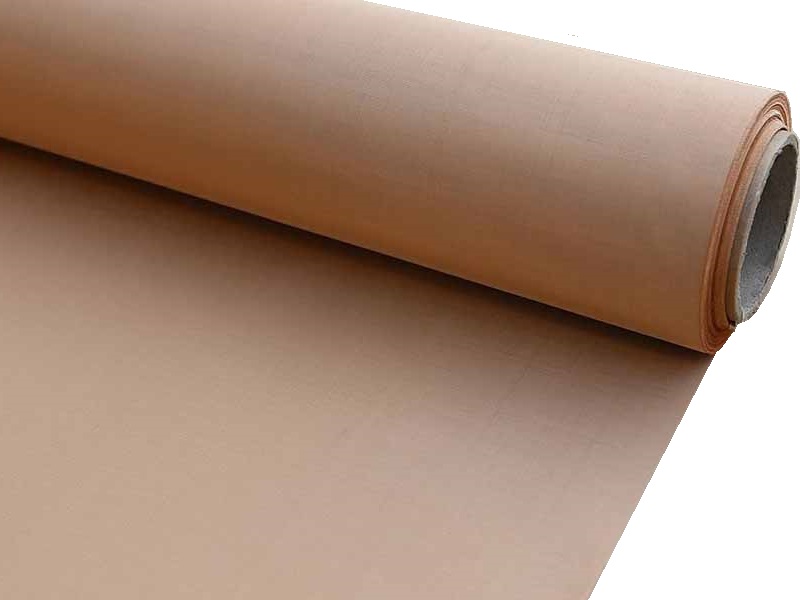

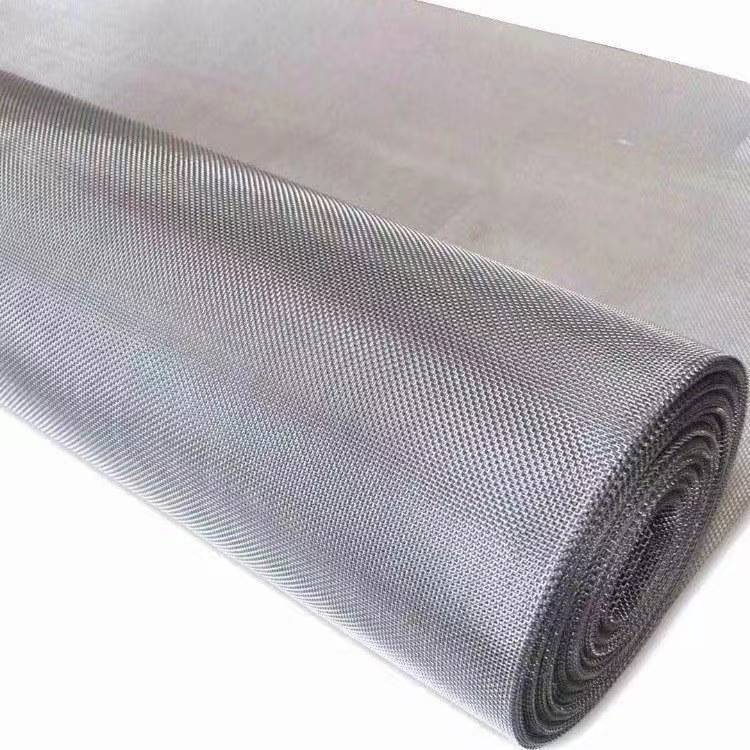

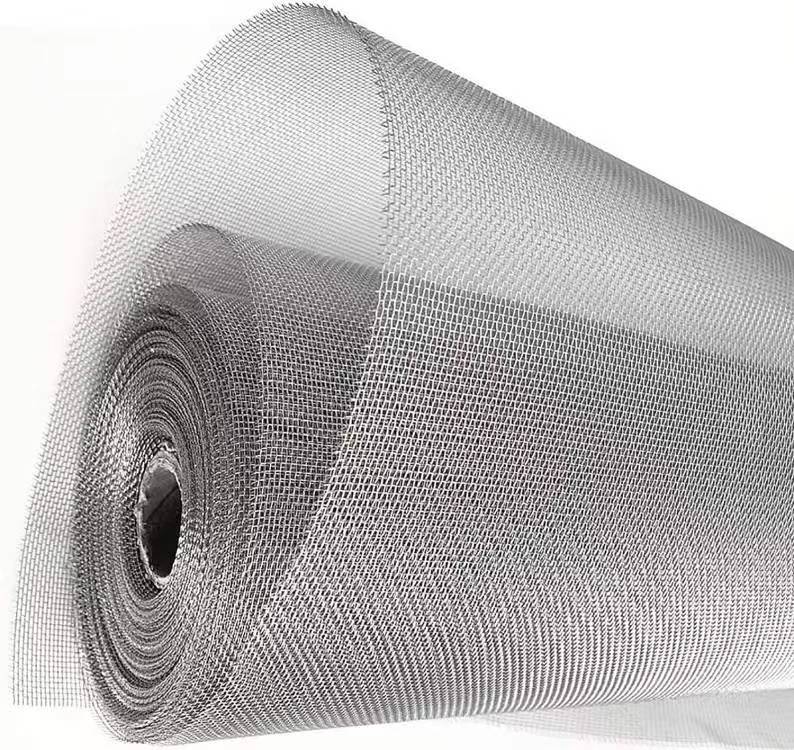

- Material Options: Test Sieves are available in various materials, including Stainless Steel grades 304, 304L, 316, 316L, and brass, to ensure suitability for different testing environments and sample types.

- Frame Material: The frames of these sieves are constructed from either stainless steel or brass, providing stability and durability for the sieves and ensuring they can withstand repeated use in various conditions.

- Surface Treatment: To enhance durability and resistance to wear, the sieves undergo surface treatments such as galvanization or electrostatic painting. This not only prolongs their lifespan but also improves their resistance to corrosive substances.

- Production Process and Hole Shapes: Manufactured through either plain weaving or perforation, the sieves can feature either square or round holes. This variety in hole shapes allows for precise and accurate particle size analysis across different materials.

- Compliance with Standards: The Test Sieves adhere to multiple international standards, including ASTM E323-11, ASTM E11-16, E161-12, ISO 565-1990, ISO 3310-1, ISO 3310-2, ISO 3310-3, ISO 2591-1, and GB/T 6003, ensuring they meet global requirements for particle analysis.

- Size and Customization: Standard sieve diameters range widely, typically from 100 mm to 450 mm, accommodating various scales of testing. Mesh sizes are customizable, ranging from very fine meshes (as small as 20 µm) for detailed particle analysis to larger meshes (up to several millimeters) for coarser sieving needs. Customization in aperture size is also available, allowing for tailored particle size separation to meet specific testing requirements.

Advantages

- Exceptional Material Quality: Constructed from premium stainless steel, brass, or aluminum, these sieves boast remarkable durability and longevity. Their materials offer excellent pliability, ensuring an extended lifespan.

- Advanced Manufacturing Techniques: Utilizing precise, automated machinery, these sieves are crafted with a high degree of accuracy. The mesh is consistently woven, firm, and free from any sharp edges, reflecting top-notch craftsmanship.

- Robust Performance Attributes: These sieves are designed to withstand friction, resist corrosion, and endure high temperatures. Their robust construction ensures reliable performance in various challenging environments.

- Tailored Design Options: With a manufacturing facility capable of custom designs, the sieves can be tailored to meet specific requirements, offering flexibility and personalization in design.

Key Features of Test Sieves

- Durable and Resilient: These sieves are characterized by their high strength, making them resistant to damage and ensuring longevity even under frequent use.

- Convenient and User-Friendly: The lightweight design of these sieves makes them easy to handle, operate, and transport, catering to various working conditions and user preferences.

- Resistant to Extreme Conditions: Built to endure, they exhibit excellent resistance to corrosion, high temperatures, and both acidic and alkaline environments, making them versatile for diverse testing scenarios.

- Versatile Screening Capabilities: Ideal for a range of materials, these sieves are proficient in handling different types of powders and particles, providing flexibility in laboratory and industrial applications.

- Adaptable to Various Environments: Designed for efficiency, they can perform sieving operations effectively in both dry and humid conditions, broadening their scope of application.

- Long-Lasting with Minimal Maintenance: Their robust construction not only promises an extended service life but also minimizes the need for maintenance, offering a cost-effective solution for sieving needs.

Applications of Test Sieves

Test sieves are not just tools for scientific analysis but are integral to a range of practical applications across different sectors. Test sieves find their primary application in several key areas, particularly for sieving soil, grain, flour, coffee powder, or conducting particle size analysis. Their versatility is showcased in various environments:

- In Gardening: These sieves are invaluable for soil sifting in gardens, ensuring optimal soil texture for plant growth.

- Laboratory Settings: They are essential in laboratories for detailed particle size analysis, crucial in scientific research and experimentation.

- Household Uses: In homes, these sieves are perfect for kitchen tasks like sieving flour or coffee powder, simplifying culinary preparations.

- Metallurgy Sector: In the metallurgy industry, test sieves are used for sorting and analyzing metal particles, aiding in quality control and research.

- Construction Industry: They are employed in construction for material grading and quality assurance, ensuring the right composition of building materials.

- Quality Inspection Departments: These sieves are pivotal in quality inspection departments for verifying the particle size and consistency of various products, ensuring adherence to industry standards.

Product Photo Showcase and Alias

General Purpose Sieves: Primarily used in sectors such as agriculture, construction, and culinary settings, these sieves serve as a fundamental tool for basic sorting and sifting tasks, from grain to construction materials.

Customized Sieves: Tailored for specific, often unconventional uses, these sieves cater to distinct needs, such as filtering rare substances or working with non-standard particle sizes, making them indispensable in niche industrial and research applications.

Research Grade Sieves: Specially designed for lab environments, these sieves are integral for precise experiments and studies, particularly in fields like pharmaceuticals and chemical research, where accuracy is paramount.

Automated Sieving Machines: These devices streamline the sieving process, offering uniform and efficient results with reduced manual input, ideal for lab and industrial settings prioritizing time-saving and consistency.

Material Analysis Sieves: These are key in lab settings for accurately measuring and analyzing particle sizes, crucial in quality control and scientific studies.

Food Industry Sieves: Primarily used in food production, these sieves are essential for sorting and grading various food grains, ensuring quality and consistency in products.

Baking Sieves: A vital tool in baking and food preparation, these sieves are used for sifting flour and other baking ingredients to achieve the desired consistency and texture.

Culinary Powder Sieves: Ideal for culinary purposes, these sieves are perfect for refining coffee powder and other fine ingredients, ensuring a uniform texture in culinary creations.