JD Hardware Wire Mesh Co., Ltd specializes in producing Stainless Steel Woven Wire Mesh, known for its exceptional versatility and durability. This mesh is notably resistant to corrosion and chemicals, making it reliable even under demanding conditions. Our range prominently features Type 304 stainless steel mesh, widely acknowledged for its quality and industry-standard performance. We offer a wide variety of mesh opening sizes and wire diameters, catering to diverse applications in industrial, architectural, food processing, and other areas. Our commitment is to meet our clients’ specific needs with precision, offering reliable and adaptable mesh products of high quality and accuracy.

Common Specifications and Sizes

- Stainless Steel Wire Types: Our stainless steel woven wire mesh is available in various grades including 304, 304L, 316, 316L, 310, 314, 410, and 430. Each grade offers unique properties such as varying degrees of corrosion resistance and strength, making them suitable for specific environments and applications.

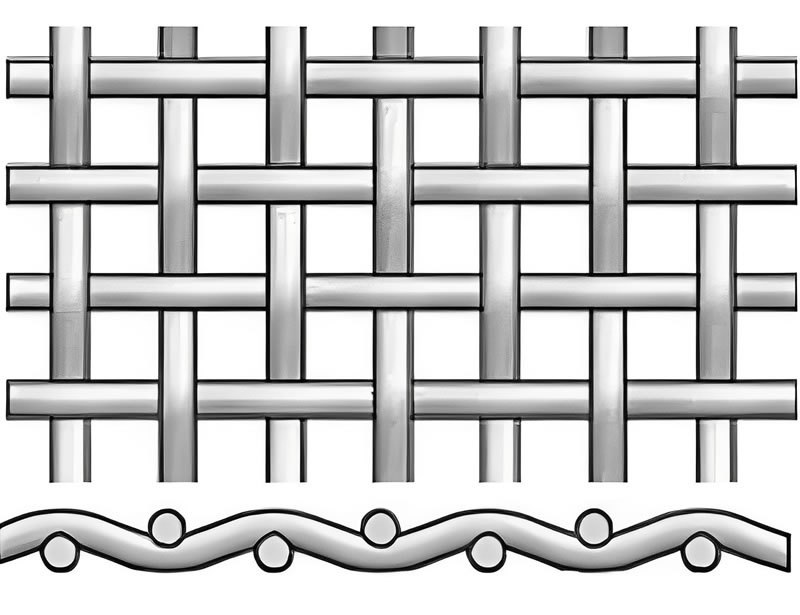

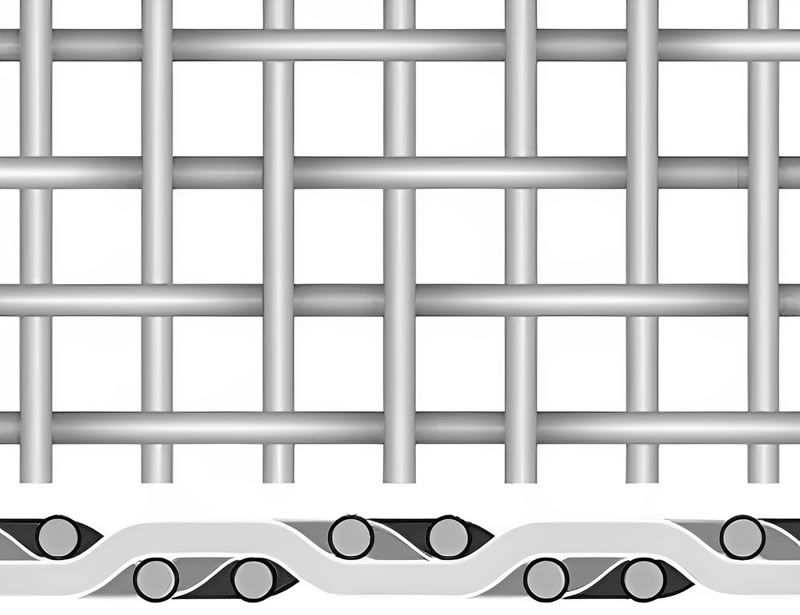

- Available Weaving Types: We offer three primary weaving styles – Plain Weave, Twill Weave, and Dutch Twill. Plain weave is most common, providing a balance of strength and openness. Twill weave allows for heavier wires and tighter meshes, suitable for finer filtration. Dutch Twill offers even finer filtration with a dense mesh structure.

- Wire Diameter Range: Our mesh can be customized with wire diameters ranging from a very fine 0.02mm up to a more robust 3.5mm. This flexibility in wire diameter allows for varied strength, flexibility, and filtration capabilities of the mesh, catering to specific needs of different applications.

- Mesh Count Range: The mesh count available spans from 2 to 625 mesh. This wide range indicates the number of openings per linear inch, offering various degrees of fineness. Lower mesh counts are more open and suited for applications requiring larger openings, while higher counts provide finer filtration.

- Open Area Percentage Range: Our mesh’s open area percentage varies from 25% to 84.6%. This measurement is essential for determining airflow, light transmission, and material pass-through levels, thereby affecting the mesh’s suitability for various filtration, screening, and architectural applications.

- Roll Dimensions: Our rolls are available in a maximum width of up to 6 meters, suitable for large projects or industrial applications. The maximum length of the rolls extends up to 500 meters, providing an ample supply for extensive use or large-scale deployments. This reduces the necessity for multiple joins or seams in applications.

| Plain weave or twill weave stainless steel wire mesh. | ||||||||

| Weave Type | Mesh Count | Wire Dia. (inch) | Width of Opening (inch) | Wire Dia. (m’m) | Width of Opening (mm) | Open Area (%) | Weigh Per 100 sq’ based on 304ss | Opening (Micron) |

| Plain | 2 x 2 | 0.08 | 0.42 | 2.03 | 10.67 | 70.6 | 83 | 10687 |

| Plain | 2 x 2 | 0.063 | 0.437 | 1.60 | 11.10 | 76.4 | 51.7 | 11119 |

| Plain | 2 x 2 | 0.054 | 0.446 | 1.37 | 11.33 | 79.6 | 37.6 | 11348 |

| Plain | 3 x 3 | 0.08 | 0.253 | 2.03 | 6.43 | 57.6 | 126.4 | 6438 |

| Plain | 3 x 3 | 0.072 | 0.261 | 1.83 | 6.63 | 61.3 | 101.9 | 6641 |

| Plain | 3 x 3 | 0.063 | 0.27 | 1.60 | 6.86 | 65.6 | 77.6 | 6870 |

| Plain | 3 x 3 | 0.054 | 0.279 | 1.37 | 7.09 | 70.1 | 57.3 | 7099 |

| Plain | 3 x 3 | 0.047 | 0.286 | 1.19 | 7.26 | 73.6 | 42.8 | 7277 |

| Plain | 3 x 3 | 0.041 | 0.2923 | 1.04 | 7.42 | 76.7 | 32.5 | 7438 |

| Plain | 4 x 4 | 0.063 | 0.187 | 1.60 | 4.75 | 56 | 105.8 | 4758 |

| Plain | 4 x 4 | 0.054 | 0.196 | 1.37 | 4.98 | 61.5 | 77.2 | 4987 |

| Plain | 4 x 4 | 0.047 | 0.203 | 1.19 | 5.16 | 65.9 | 58.2 | 5165 |

| Plain | 4 x 4 | 0.041 | 0.209 | 1.04 | 5.31 | 69.9 | 44 | 5318 |

| Plain | 4 x 4 | 0.035 | 0.215 | 0.89 | 5.46 | 74 | 32 | 5471 |

| Plain | 5 x 5 | 0.054 | 0.146 | 1.37 | 3.71 | 53.3 | 97.7 | 3715 |

| Plain | 5 x 5 | 0.047 | 0.153 | 1.19 | 3.89 | 58.5 | 73.3 | 3893 |

| Plain | 5 x 5 | 0.041 | 0.159 | 1.04 | 4.04 | 63.2 | 55.4 | 4046 |

| Plain | 5 x 5 | 0.032 | 0.168 | 0.81 | 4.27 | 70.6 | 33.5 | 4275 |

| Plain | 6 x 6 | 0.047 | 0.12 | 1.19 | 3.05 | 51.8 | 89.1 | 3053 |

| Plain | 6 x 6 | 0.041 | 0.126 | 1.04 | 3.20 | 57.2 | 67.2 | 3206 |

| Plain | 6 x 6 | 0.035 | 0.132 | 0.89 | 3.35 | 62.7 | 48.6 | 3359 |

| Plain | 6 x 6 | 0.032 | 0.135 | 0.81 | 3.43 | 65.6 | 20.7 | 3435 |

| Plain | 8 X 8 | 0.047 | 0.078 | 1.19 | 1.98 | 38.9 | 122.1 | 1985 |

| Plain | 8 X 8 | 0.041 | 0.084 | 1.04 | 2.13 | 45.2 | 91.5 | 2137 |

| Plain | 8 X 8 | 0.035 | 0.09 | 0.89 | 2.29 | 51.8 | 65.1 | 2290 |

| Plain | 8 X 8 | 0.028 | 0.097 | 0.71 | 2.46 | 60.2 | 47.1 | 2468 |

| Plain | 10 x 10 | 0.041 | 0.059 | 1.04 | 1.50 | 34.8 | 117.5 | 1501 |

| Plain | 10 x 10 | 0.032 | 0.068 | 0.81 | 1.73 | 46.2 | 69.5 | 1730 |

| Plain | 10 x 10 | 0.025 | 0.075 | 0.64 | 1.91 | 56.3 | 41.6 | 1908 |

| Plain | 10 x 10 | 0.02 | 0.08 | 0.51 | 2.03 | 64 | 26.4 | 2036 |

| Plain | 12 x 12 | 0.028 | 0.055 | 0.71 | 1.40 | 43.6 | 64.1 | 1399 |

| Plain | 12 x 12 | 0.025 | 0.058 | 0.64 | 1.47 | 48.4 | 50.6 | 1476 |

| Plain | 12 x 12 | 0.02 | 0.063 | 0.51 | 1.60 | 57.2 | 31.9 | 1603 |

| Plain | 12 x 12 | 0.018 | 0.065 | 0.46 | 1.65 | 60.8 | 25.8 | 1654 |

| Plain | 14 x 14 | 0.025 | 0.046 | 0.64 | 1.17 | 41.5 | 59.9 | 1170 |

| Plain | 14 x 14 | 0.02 | 0.051 | 0.51 | 1.30 | 51 | 37.6 | 1298 |

| Plain | 14 x 14 | 0.018 | 0.053 | 0.46 | 1.35 | 55.1 | 37.6 | 1349 |

| Plain | 14 x 14 | 0.017 | 0.054 | 0.43 | 1.37 | 57.2 | 26.9 | 1374 |

| Plain | 16 x 16 | 0.023 | 0.0395 | 0.58 | 1.00 | 39.9 | 58.3 | 1005 |

| Plain | 16 x 16 | 0.02 | 0.0425 | 0.51 | 1.08 | 46.2 | 43.4 | 1081 |

| Plain | 16 x 16 | 0.018 | 0.0445 | 0.46 | 1.13 | 50.7 | 34.8 | 1132 |

| Plain | 16 x 16 | 0.016 | 0.0465 | 0.41 | 1.18 | 55.4 | 27.4 | 1183 |

| Plain | 18 x 18 | 0.023 | 0.0326 | 0.58 | 0.83 | 34.4 | 66.7 | 830 |

| Plain | 18 x 18 | 0.02 | 0.0356 | 0.51 | 0.90 | 41.1 | 49.5 | 906 |

| Plain | 18 x 18 | 0.018 | 0.0376 | 0.46 | 0.96 | 45.8 | 39.6 | 957 |

| Plain | 18 x 18 | 0.016 | 0.0396 | 0.41 | 1.01 | 50.8 | 31 | 1008 |

| Plain | 18 x 18 | 0.0135 | 0.0421 | 0.34 | 1.07 | 57.4 | 21.8 | 1071 |

| Plain | 20 x 20 | 0.023 | 0.027 | 0.58 | 0.69 | 29.2 | 71.5 | 687 |

| Plain | 20 x 20 | 0.02 | 0.03 | 0.51 | 0.76 | 36 | 55.8 | 763 |

| Plain | 20 x 20 | 0.018 | 0.032 | 0.46 | 0.81 | 41 | 44.5 | 814 |

| Plain | 20 x 20 | 0.016 | 0.034 | 0.41 | 0.86 | 46.2 | 34.7 | 865 |

| Plain | 20 x 20 | 0.014 | 0.036 | 0.36 | 0.91 | 51.8 | 26.4 | 916 |

| Plain | 20 x 20 | 0.013 | 0.037 | 0.33 | 0.94 | 54.8 | 22.6 | 941 |

| Plain | 24 x 24 | 0.016 | 0.0257 | 0.41 | 0.65 | 38 | 42.5 | 654 |

| Plain | 24 x 24 | 0.014 | 0.0277 | 0.36 | 0.70 | 44.2 | 32.1 | 705 |

| Plain | 24 x 24 | 0.012 | 0.0297 | 0.30 | 0.75 | 50.8 | 23.2 | 756 |

| Plain | 24 x 24 | 0.01 | 0.0317 | 0.25 | 0.81 | 57.9 | 16 | 807 |

| Plain | 24 x 24 | 0.0075 | 0.0342 | 0.19 | 0.87 | 67.2 | 8.9 | 870 |

| Twill | 30 x 30 | 0.015 | 0.0183 | 0.38 | 0.46 | 30.1 | 47.9 | 466 |

| Twill | 30 x 30 | 0.014 | 0.0193 | 0.36 | 0.49 | 33.5 | 41.2 | 491 |

| Plain | 30 x 30 | 0.0135 | 0.0198 | 0.34 | 0.50 | 35.3 | 38.2 | 504 |

| Plain | 30 x 30 | 0.012 | 0.0213 | 0.30 | 0.54 | 40.8 | 29.7 | 542 |

| Plain | 30 x 30 | 0.01 | 0.0233 | 0.25 | 0.59 | 48.9 | 20.2 | 593 |

| Plain | 30 x 30 | 0.0085 | 0.0248 | 0.22 | 0.63 | 55.4 | 14.4 | 631 |

| Plain | 36 x 36 | 0.0065 | 0.0213 | 0.17 | 0.54 | 58.7 | 10.2 | 542 |

| Plain | 36 x 36 | 0.009 | 0.0188 | 0.23 | 0.48 | 45.8 | 21.63 | 478 |

| Plain | 40 x 40 | 0.011 | 0.014 | 0.28 | 0.36 | 31.4 | 34.1 | 356 |

| Plain | 40 x 40 | 0.01 | 0.015 | 0.25 | 0.38 | 36 | 27.9 | 382 |

| Plain | 40 x 40 | 0.009 | 0.016 | 0.23 | 0.41 | 41 | 22.2 | 407 |

| Plain | 40 x 40 | 0.008 | 0.017 | 0.20 | 0.43 | 46.2 | 17.2 | 433 |

| Plain | 40 x 40 | 0.0065 | 0.0185 | 0.17 | 0.47 | 54.8 | 11.3 | 471 |

| Plain | 50 x 50 | 0.009 | 0.011 | 0.23 | 0.28 | 30.3 | 28.7 | 280 |

| Plain | 50 x 50 | 0.008 | 0.012 | 0.20 | 0.30 | 36 | 22.3 | 305 |

| Plain | 50 x 50 | 0.0075 | 0.0125 | 0.19 | 0.32 | 39.1 | 19.4 | 318 |

| Plain | 50 x 50 | 0.0055 | 0.0145 | 0.14 | 0.37 | 52.6 | 10.1 | 369 |

| Twill | 60 x 60 | 0.01 | 0.0067 | 0.25 | 0.17 | 16.2 | 38.3 | 170 |

| Plain | 60 x 60 | 0.0075 | 0.0092 | 0.19 | 0.23 | 30.5 | 23.9 | 234 |

| Plain | 60 x 60 | 0.007 | 0.0097 | 0.18 | 0.25 | 33.9 | 20.6 | 247 |

| Plain | 60 x 60 | 0.006 | 0.0107 | 0.15 | 0.27 | 41.2 | 14.8 | 272 |

| Plain | 70 x 70 | 0.0057 | 0.0078 | 0.14 | 0.20 | 29.8 | 21 | 198 |

| Plain | 70 x 70 | 0.0047 | 0.0096 | 0.12 | 0.24 | 54.9 | 6 | 407 |

| Twill | 80 x 80 | 0.007 | 0.0055 | 0.18 | 0.14 | 19.4 | 27.7 | 140 |

| Plain | 80 x 80 | 0.0055 | 0.007 | 0.14 | 0.18 | 31.4 | 17.1 | 178 |

| Plain | 80 x 80 | 0.0047 | 0.0077 | 0.12 | 0.20 | 49.6 | 6.9 | 224 |

| Plain | 100 x 100 | 0.0045 | 0.0055 | 0.11 | 0.14 | 30.3 | 14.3 | 140 |

| Plain | 100 x 100 | 0.004 | 0.006 | 0.10 | 0.15 | 36 | 11.1 | 153 |

| Plain | 120 x 120 | 0.0037 | 0.0046 | 0.09 | 0.12 | 30.7 | 10.3 | 117 |

| Plain | 120 x 120 | 0.0032 | 0.0052 | 0.08 | 0.13 | 47.3 | 5 | 148 |

| Plain | 150 x 150 | 0.0026 | 0.0041 | 0.07 | 0.10 | 37.4 | 7.2 | 104 |

| Plain | 165 x 165 | 0.0019 | 0.0042 | 0.05 | 0.11 | 47.1 | 4.2 | 107 |

| Plain | 180 x 180 | 0.0023 | 0.0033 | 0.06 | 0.08 | 34.7 | 7.5 | 84 |

| Plain | 200 x 200 | 0.0023 | 0.0027 | 0.06 | 0.07 | 29.1 | 7.3 | 69 |

| Plain | 200 x 200 | 0.0021 | 0.0029 | 0.05 | 0.07 | 33.6 | 6.3 | 74 |

| Plain | 230 x 230 | 0.0014 | 0.0029 | 0.04 | 0.07 | 46 | 3.4 | 74 |

| Plain | 250 x 250 | 0.0016 | 0.0024 | 0.04 | 0.06 | 36 | 4.3 | 61 |

| Twill | 270 x 270 | 0.0016 | 0.0021 | 0.04 | 0.05 | 32.2 | 4.8 | 53 |

| Plain | 300 x 300 | 0.0012 | 0.0018 | 0.03 | 0.05 | 29.7 | 3 | 46 |

| Twill | 325 x 325 | 0.0014 | 0.0017 | 0.04 | 0.04 | 30 | 4.3 | 43 |

| Twill | 400 x 400 | 0.0011 | 0.0014 | 0.03 | 0.04 | 31.4 | 3.4 | 36 |

| Twill | 500 x 500 | 0.001 | 0.001 | 0.03 | 0.03 | 25 | * | 25 |

| Twill | 635 x 635 | 0.0008 | 0.0008 | 0.02 | 0.02 | 25 | * | 20 |

This detailed specification range demonstrates our capability to tailor stainless steel woven wire mesh to a wide array of requirements, ensuring optimal performance for each unique application.

Chemical Composition

| ASTM | C | Si | Mn | P | S | Ni | Cr | Mu | Cu |

| 302 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 8.00~10.00 | 17.00~19.00 | – | – |

| 304 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 8.00~10.00 | 18.00~20.00 | ≤0.60 | – |

| 304HC | ≤0.06 | ≤1.00 | ≤2.00 | ≤0.040 | ≤0.015 | 8.00~10.00 | 18.00~19.00 | – | 1.00~3.00 |

| 304L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 8.00~12.00 | 18.00~20.00 | – | – |

| 305 | ≤0.12 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 10.50~13.00 | 17.00~19.00 | – | – |

| 310S | ≤0.08 | ≤1.50 | ≤2.00 | ≤0.045 | ≤0.030 | 19.00~22.00 | 24.00~26.00 | ≤0.50 | – |

| 314 | ≤0.25 | 1.50~3.00 | ≤2.00 | ≤0.045 | ≤0.030 | 19.00~22.00 | 23.00~26.00 | – | – |

| 316 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 10.00~14.00 | 16.00~18.00 | 2.00~3.00 | – |

| 316L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 10.00~14.00 | 16.00~18.00 | 2.00~3.00 | – |

| 410 | 0.08~0.15 | ≤1.00 | ≤1.00 | ≤0.040 | ≤0.010 | ≤0.60 | 11.50~13.00 | – | – |

| 430 | ≤0.08 | ≤1.00 | ≤1.00 | ≤0.040 | ≤0.010 | ≤0.60 | 16.00~18.00 | – | – |

Features

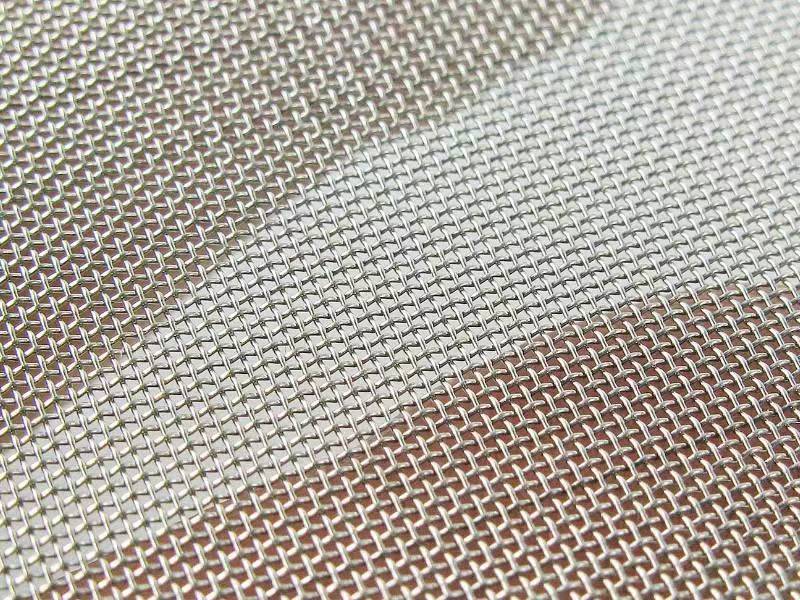

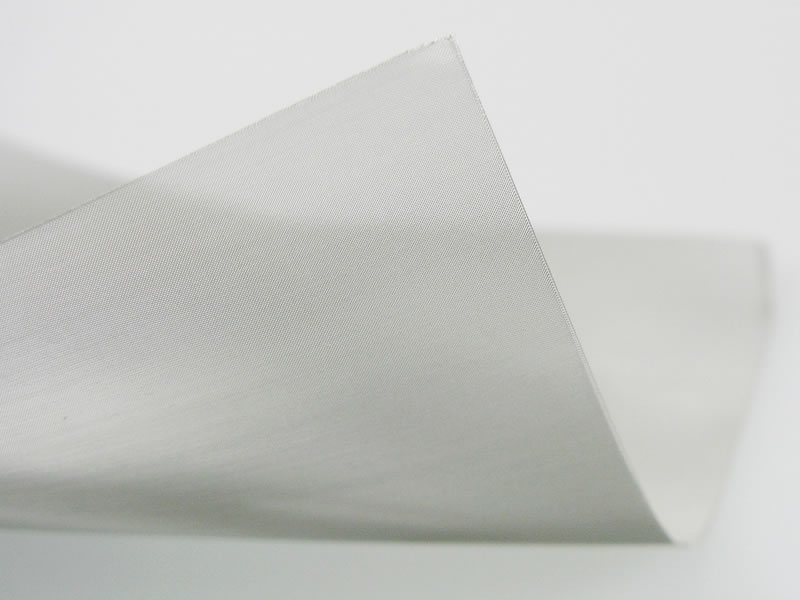

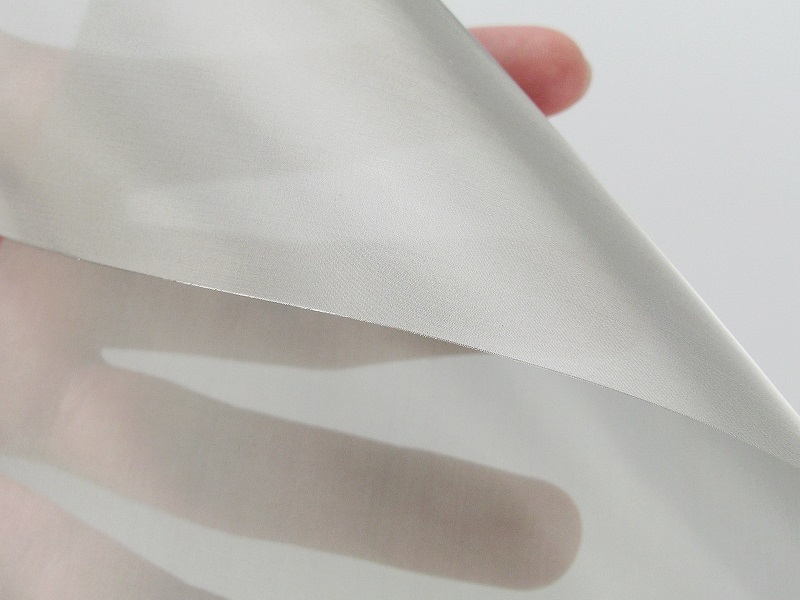

- Uniform and Sleek Surface: The mesh boasts a smooth, even surface.

- Robust Mechanical Properties: It exhibits strong mechanical strength.

- High Corrosion Resistance: The mesh is highly resistant to corrosion, enhancing its longevity.

- Durability and Abrasion Resistance: Notably durable, it also resists abrasion well.

- Chemical Resistance: It can withstand various chemical exposures.

- Ease of Modification: The mesh can be easily cut using standard tools.

- Versatile Use: Its extreme versatility makes it suitable for numerous applications.

- Wide Range of Specifications: Available in numerous specifications to suit diverse needs.

Applications

- Screening and Filtering: Ideal for use in environments with acid or alkali exposure, such as in the chemical industry.

- Oil Industry: Serves as mud mesh in oil production processes.

- Chemical Packing Nets: Used in the chemical industry for packing applications.

- Screen Mesh in Chemical Fiber Industry: Acts as a screen mesh in the production of chemical fibers.

- Electroplating Industry: Utilized as pickling nets in electroplating processes, offering resistance to corrosive substances.

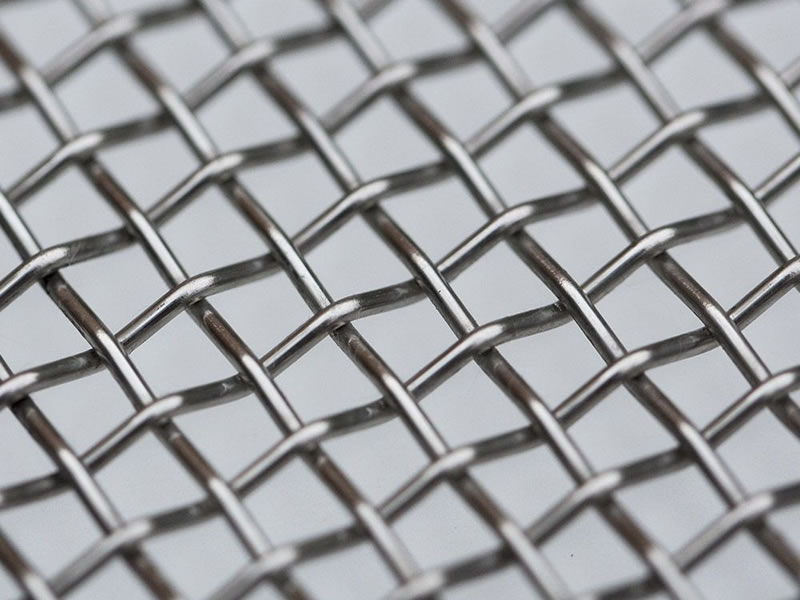

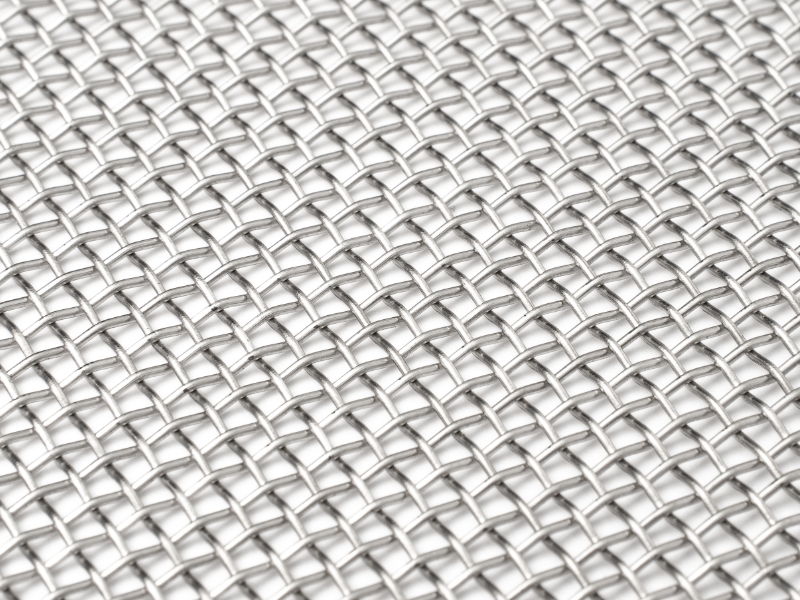

Product Photo Showcase and Alias

Stainless Steel Woven Mesh

This mesh is characterized by its interwoven structure, providing strength and versatility. It’s widely used in industrial and architectural applications due to its durability and corrosion resistance.

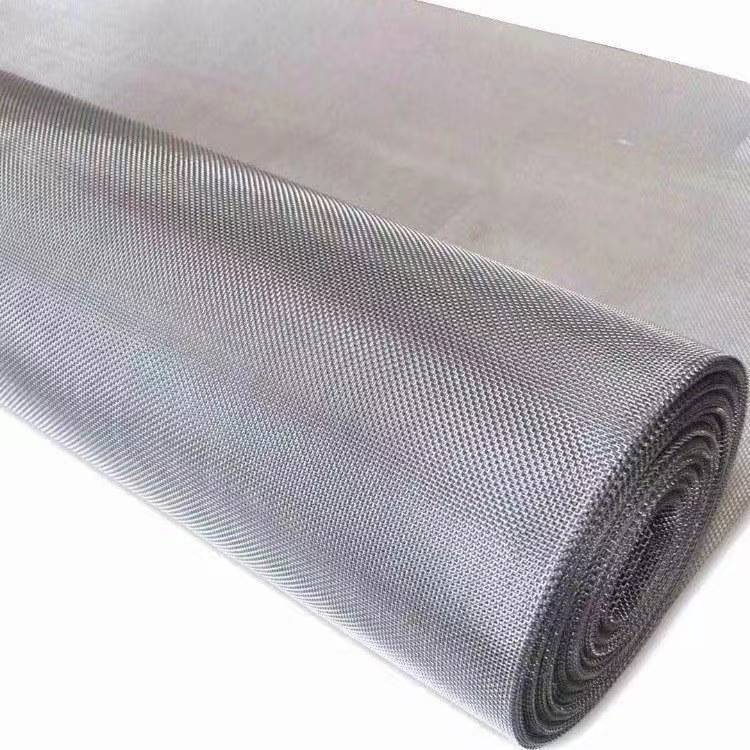

Stainless Steel Wire Screen

Primarily used in screening processes, this variant is known for its precision and uniform openings. It’s a go-to option for sieving and filtration in numerous industrial sectors.

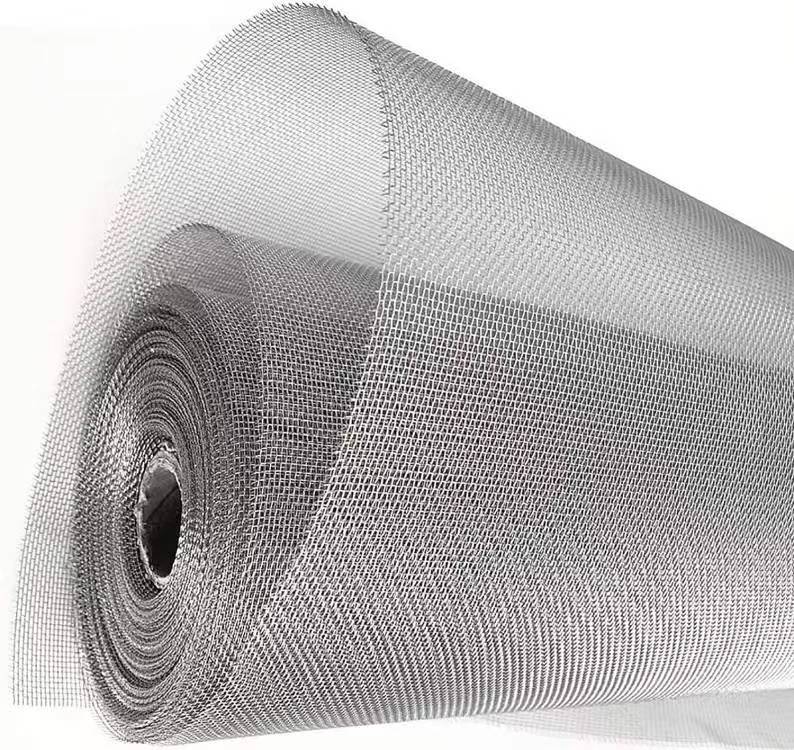

SS Filter Mesh

As the name suggests, SS Filter Mesh is specifically designed for filtration purposes. It effectively separates and purifies liquids and gases in various industrial and environmental applications.

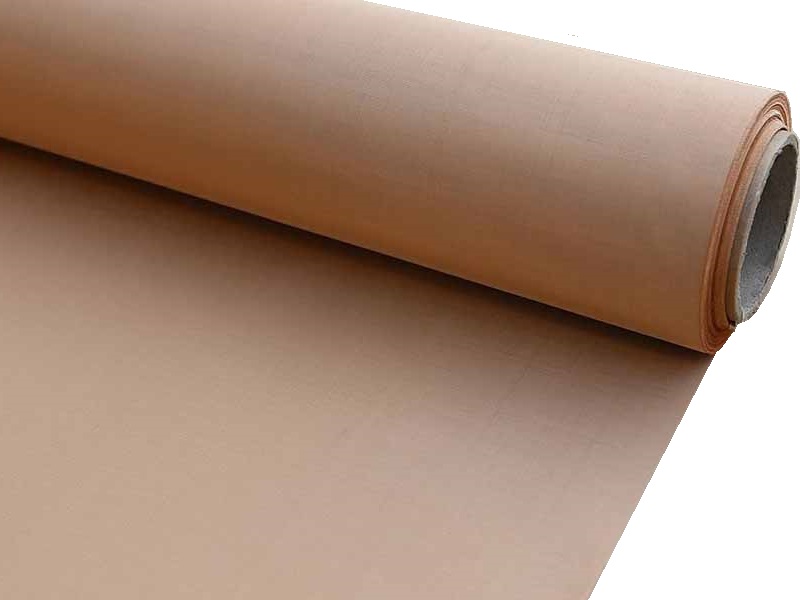

Stainless Steel Mesh Fabric

This term emphasizes the fabric-like flexibility of the mesh, making it suitable for applications requiring a blend of strength and pliability, such as in certain architectural or design projects.

SS Woven Wire

SS Woven Wire is recognized for its intricate weaving technique, which provides both durability and fine filtration capabilities, ideal for intricate filtering and screening operations in various industries.

SS Woven Wire Filter

This name underscores its use in filtration, where precision and reliability are paramount. It’s widely used in the food, chemical, and pharmaceutical industries for filtering solids, liquids, and gases.