JD Hardware Wire Mesh Co., Ltd specializes in producing Knitted Wire Mesh, known as foam catching or woven screen mesh. This unique mesh is key in making screen demisters, oil and gas separators, and dust removal systems. It plays a vital role in environmental protection, reducing engine noise, and dampening mechanical shocks. Our Knitted Wire Mesh is highly versatile, widely used in the automotive and electronics industries to meet various requirements. We are committed to providing high-quality, adaptable wire mesh solutions for diverse industrial needs.

General specifications

- Material Variety in Knitted Wire Mesh

Our Knitted Wire Mesh is available in a wide range of materials to suit diverse applications. These include various types of stainless steel such as 304, 316, 430, 317, 310S, 321, 410 . We also offer other metals like brass, copper, monel, nickel, titanium, 1Cr18Ni9Ti, Cr20Ni80, and Cr20Ni50, catering to specific needs and environments. - Wire Diameter Specifications

The wire diameter of our Knitted Wire Mesh ranges from 0.1mm to 0.55mm, available in both flat and round wire options. The most commonly used diameters are between 0.20mm and 0.25mm, balancing strength and flexibility. - Hole Size and Shape

Our mesh comes in various hole sizes including 4mm×3mm, 5mm×6mm, 2mmx4mm, and 4mmx5mm, among others. The hole shape is irregular, offering unique filtering capabilities. - Range of Widths

We provide Knitted Wire Mesh in a range of widths from 40mm up to 600mm, with popular sizes including 80mm, 100mm, 150mm, 200mm, 300mm, 400mm, and 500mm, accommodating different scale requirements. - Length Options and Customization

Standard lengths of our mesh range from 30 meters to 200 meters, with the option for customization to meet specific length requirements. - Thickness Variability

The thickness of our Knitted Wire Mesh varies from 0.12mm to 2.5mm. Customized thickness options are also available, allowing for a tailored approach to different applications. - Craftsmanship and Design

Our mesh is crafted through layered, spiral wound, or compressed techniques, creating a tortuous path that is highly effective for particle capture. This craftsmanship enhances the mesh’s filtering efficiency. - Surface Type Selection

We offer two main surface types for our Knitted Wire Mesh: flat-type and corrugated type. Each type serves different functional purposes, depending on the application.

Type

Knitted wire mesh, adaptable for various applications, comes in different forms. It can be made with either flattened or round wires, leading to two types: Round Wire Knitted Wire Mesh and Flat Wire Knitted Wire Mesh. Additionally, based on the filament used, it’s available as either Mono-filament Knitted Wire Mesh or Multi-filament Knitted Wire Mesh, each serving specific industrial requirements.

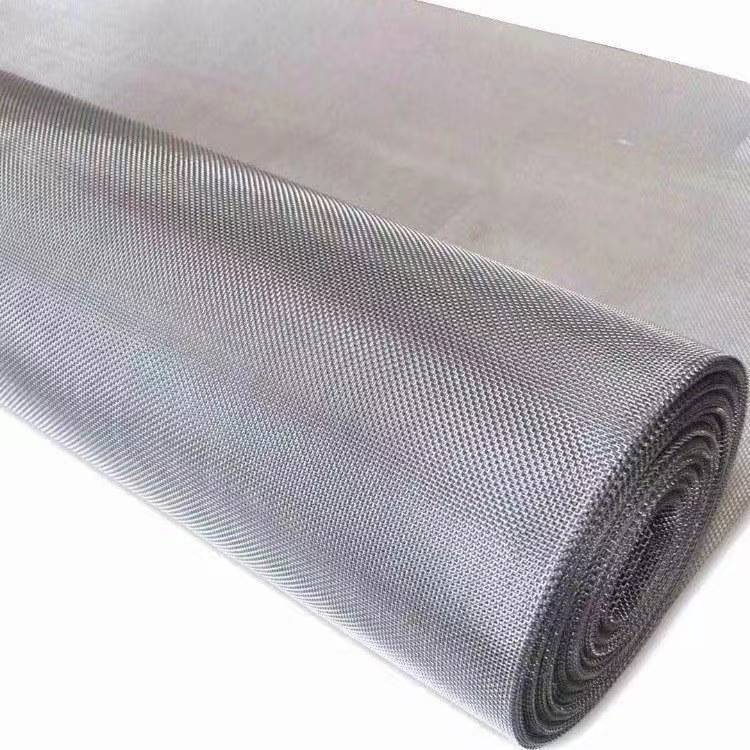

Round Wire Knitted Wire Mesh

This type of mesh is made using round wires. Round wire knitted mesh is known for its flexibility and strength, making it suitable for applications where these attributes are crucial. Its rounded surface is ideal for filtration and separation processes, as it provides an even and consistent mesh structure.

Flat Wire Knitted Wire Mesh

Constructed with flat wires, this mesh offers a larger surface area compared to round wire mesh. This characteristic makes it highly effective for applications requiring more extensive contact with the mesh surface, such as in certain types of filtration and shielding. The flat wire mesh also tends to be more robust, providing greater durability in demanding environments.

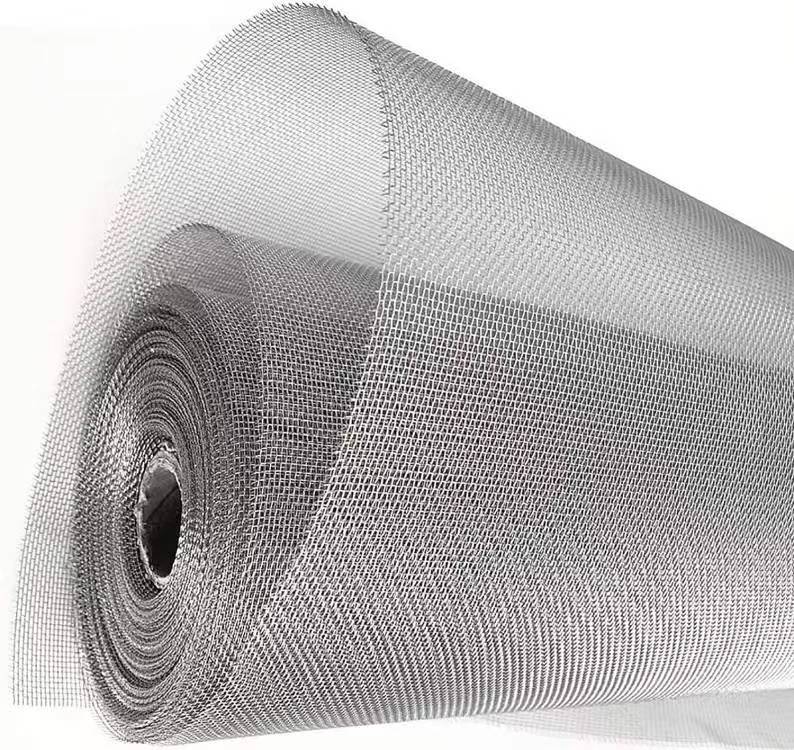

Mono-filament Knitted Wire Mesh

This mesh is made using single-strand wires, known as mono-filaments. Mono-filament knitted wire mesh is characterized by its uniformity and precision in mesh openings. It’s particularly effective in applications where accuracy and fine filtration are essential, such as in certain medical or laboratory settings.

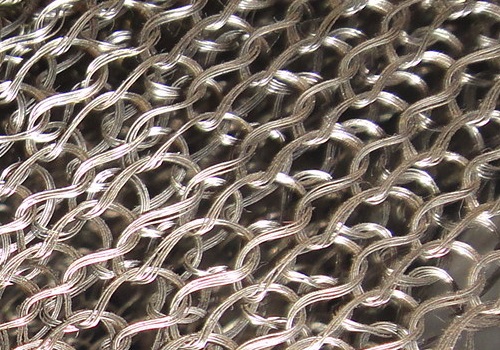

Multi-filament Knitted Wire Mesh

Constructed from multiple strands of wire woven together, multi-filament knitted wire mesh offers enhanced strength and durability. This type is ideal for heavy-duty applications where the mesh needs to withstand high stress or pressure. It’s often used in industrial settings for applications like vibration dampening, sound attenuation, and heavy filtration.

Consolidated Features of Knitted Wire Mesh

- Durable and Stable Construction: The interlocking design and loops of the mesh create a robust and firm structure, ensuring it stays intact and does not loosen during use.

- Exceptional Filtration Efficiency: Its design makes it highly effective for demister pads, offering outstanding filtering performance, particularly in separating gas and liquid.

- Resistant to Various Elements: Demonstrates strong resistance to corrosion, rust, acids, alkalis, and extreme temperatures, suitable for harsh environments.

- Material Adaptability: Available in various materials, it can be tailored for specific requirements in different settings.

Versatile Applications of Knitted Wire Mesh

Knitted wire mesh, with its combination of strength, adaptability, and resistance properties, finds extensive applications across various industries, from technology to culinary, underscoring its importance in modern applications.

- Separation Processes: Widely used in demister pads for efficient gas and liquid separation.

- Noise and Vibration Control: Ideal in engine applications for reducing noise and absorbing shocks, thereby enhancing performance and equipment longevity.

- Protective Shielding: Effective as a barrier against electromagnetic and radio-frequency interference, crucial for safeguarding sensitive electronic devices.

- Cleaning and Culinary Uses: Due to its resilience and durability, it’s suitable for components in cleaning appliances and kitchen equipment.

Aliases

- Knitted Metal Mesh: Referred to as knitted metal mesh, it underscores its metallic composition. Ideal for applications requiring metal properties like conductivity and heat resistance, it’s a staple in various industries.

- Knitted Wire Cloth: Often called knitted wire cloth, this form is notable for its fine, cloth-like appearance. It’s especially suited for delicate tasks such as small-scale filtration and electronic shielding.

- Knitted Wire Fabric: As knitted wire fabric, it is celebrated for its fabric-like flexibility. This makes it perfect for applications that demand malleability, such as in custom-shaped filters and intricate designs.

- Knitted Wire Netting:Known as knitted wire netting, this name highlights its net-like design. It’s commonly used in scenarios needing a more open weave, such as certain types of protective barriers and screens.