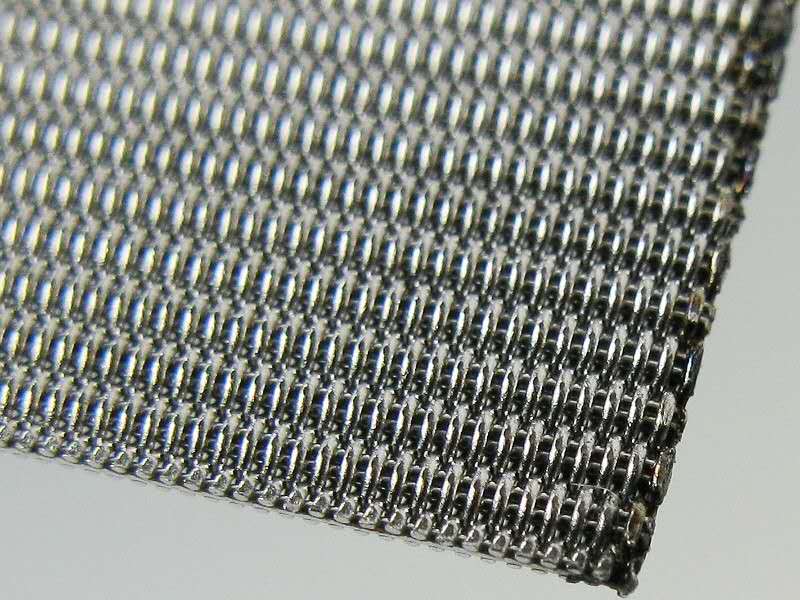

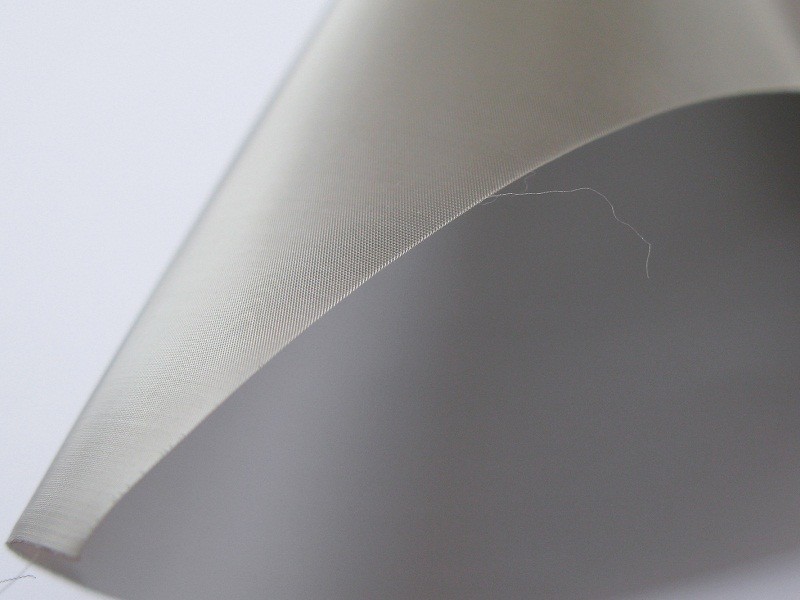

JD Hardware Wire Mesh Co., Ltd, specialize in the manufacture and export of Dutch Weave Stainless Steel Wire Mesh products, commonly referred to as Dutch Cloth, Dense Mesh, or Hole-less Mesh. Our product is a uniquely crafted filter screen, distinguished by a specialized weaving process that creates a tightly woven structure. Available in both plain weave and twill weave varieties, our Dutch Weave Stainless Steel Wire Mesh is adaptable for a wide range of applications. It is acknowledged for its exceptional durability, precise filtration, and effectiveness in various industrial and engineering contexts. Our commitment is to deliver a product that meets the specific needs of our customers, ensuring quality and reliability in every mesh.

Features

- Resistance Qualities: Resistant to acids, alkalis, and high temperatures, it also shows strong tension and excellent abrasion resistance.

- Stability and Precision: Known for stable, fine, and precise filtering, this is due to its specialized weave.

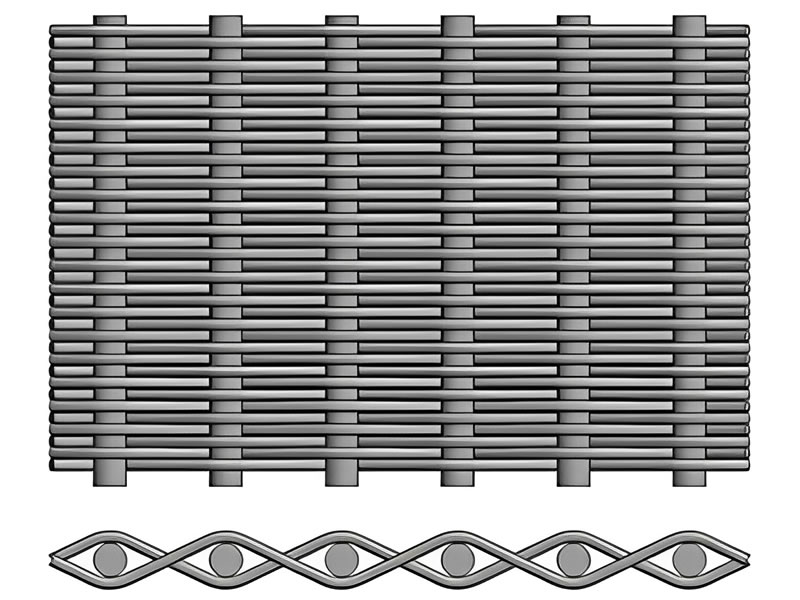

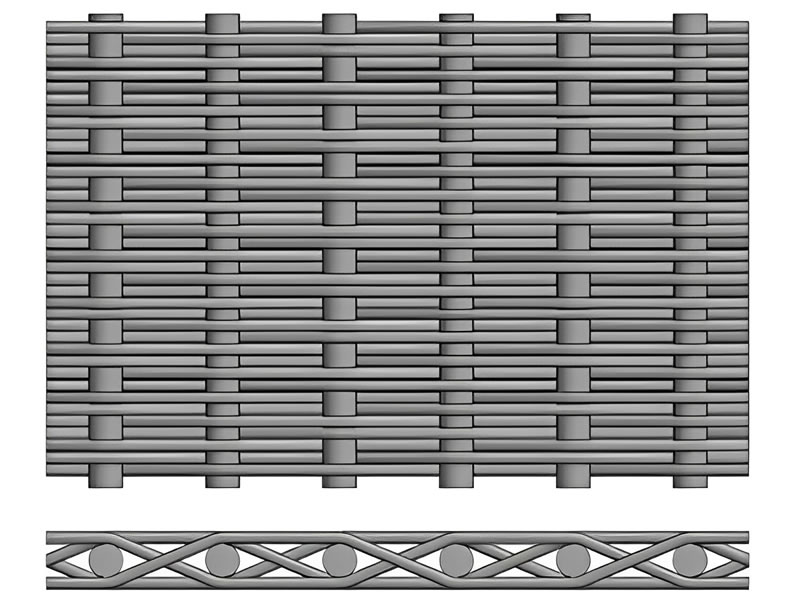

- Warp and Weft Mesh Numbers: The mesh has different warp and weft wire numbers, with weft wires typically outnumbering warp wires in a standard Dutch Weave.

- Wire Thickness: The warp wires are thicker than the weft wires, which enhances the mesh’s strength and filtration capability.

- Filter Precision: Its unique weave allows for greater filtration precision than ordinary square-hole stainless meshes, ideal for fine filtration.

- Performance under Pressure: Notably, it efficiently filters oil in high mesh number settings, but this is dependent on pressure, a crucial factor in many industrial processes.

Applications

This versatility underlines the mesh’s adaptability and effectiveness in a range of demanding industrial and scientific settings.

- Precision Screening and Oil Filtering: Its tightly arranged weft wires make it suitable for precision screening and oil filtering, especially in the petroleum industry.

- Filtration and Separation: Primarily used for gas and liquid filtration, it effectively separates various mediums.

- Use in Filters: It’s widely utilized in precision pressure filters, fuel filters, and vacuum filters, serving as a key filtering material.

- Diverse Industrial Applications: The mesh finds applications across numerous sectors, including aerospace, petroleum, chemical, chemical fiber, rubber, tire manufacturing, metallurgy, medicine, food, scientific research, and transportation.

General specifications

Dutch Weave Stainless Steel Wire Mesh comes in various materials, including SS 201, 304, 304L, 316, 316L, 321, and 430. Wire diameters range from 0.02mm to 2.0mm. The mesh count varies from 85 to 2300, catering to diverse filtration needs. These meshes offer an open area percentage between 25% and 84.6%, providing different levels of permeability. Available in roll widths up to 6 meters and lengths up to 200 meters, they suit various application sizes. This wide range of sizes and materials, coupled with customization options, enables precise adaptation to specific requirements.

| Plain dutch weave stainless steel wire mesh(Plain-Dutch) | |||||

| Mesh | Wire Dia (mm) | Wire Dia (mm) | Thickness | Weight, | Fineness of Filtering |

| Warp x Shute | Warp | Weft | (mm.) | (kg/ sq. m.) | (micron) |

| 8×85 | 0.36 | 0.32 | 0.99 | 2.57 | 310 |

| 10×56 | 0.71 | 0.5 | 1.95 | 4.76 | 305 |

| 10×70 | 0.6 | 0.4 | 1.42 | 3.7 | 300 |

| 10×88 | 0.5 | 0.33 | 0.83 | 3.02 | 265 |

| 12×64 | 0.6 | 0.42 | 1.45 | 3.9 | 250 |

| 12×95 | 0.5 | 0.3 | 0.84 | 2.89 | 220 |

| 14×88 | 0.5 | 0.32 | 1.14 | 3.13 | 250 |

| 14×110 | 0.36 | 0.25 | 0.85 | 2.22 | 220 |

| 16×80 | 0.43 | 0.38 | 1.05 | 3.05 | 260 |

| 16×120 | 0.36 | 0.24 | 0.86 | 2.25 | 150 |

| 20×150 | 0.25 | 0.18 | 0.61 | 1.53 | 120 |

| 24×110 | 0.35 | 0.25 | 0.71 | 2.33 | 105 |

| 24×120 | 0.33 | 0.23 | 0.8 | 2.2 | 100 |

| 30×150 | 0.23 | 0.18 | 0.5 | 1.6 | 90 |

| 40×200 | 0.18 | 0.14 | 0.4 | 1.3 | 80 |

| 50×250 | 0.14 | 0.112 | 0.36 | 1.03 | 55 |

| 50×280 | 0.14 | 0.1 | 0.33 | 0.95 | 50 |

| 60×300 | 0.14 | 0.09 | 0.3 | 0.92 | 45 |

| 70×400 | 0.12 | 0.071 | 0.28 | 0.92 | 42 |

| 80×400 | 0.125 | 0.071 | 0.25 | 0.82 | 40 |

| Twill dutch weave stainless steel wire mesh(Twill-Dutch) | |||||

| Mesh Per Inch | Warp Diameter | Shute Diameter | Thickness | Weight | Micron |

| Warp x Shute | (mm.) | (mm.) | (mm.) | (kg./sq. m) | Retention |

| 14×128 | 0.5 | 0.4 | 1.31 | 5.81 | 225 |

| 18×210 | 0.457 | 0.254 | 1.06 | 4.28 | 200 |

| 20×250 | 0.25 | 0.22 | 0.66 | 3.35 | 100 |

| 30×250 | 0.25 | 0.2 | 0.65 | 3.1 | 90 |

| 30×360 | 0.25 | 0.15 | 0.6 | 2.49 | 80 |

| 40×550 | 0.18 | 0.1 | 0.43 | 1.7 | 65 |

| 50×500 | 0.14 | 0.11 | 0.35 | 1.76 | 50 |

| 60×700 | 0.165 | 0.076 | 0.4 | 1.42 | 40 |

| 80×700 | 0.1 | 0.076 | 0.27 | 1.21 | 30 |

| 110×850 | 0.09 | 0.065 | 0.24 | 1.12 | 20 |

| 165×800 | 0.07 | 0.05 | 0.17 | 0.72 | 15 |

| 165×1400 | 0.07 | 0.04 | 0.16 | 0.76 | 10 |

| 200×600 | 0.06 | 0.046 | 0.15 | 0.5 | 8 |

| 200×1400 | 0.07 | 0.04 | 0.15 | 0.83 | 5 |

| 250×2000 | 0.04 | 0.028 | 0.1 | 0.49 | 3 |

| 325×2300 | 0.038 | 0.025 | 0.09 | 0.47 | 2 |

| 400×2800 | 0.029 | 0.023 | 0.07 | 0.45 | 1.5 |

| 500×3500 | 0.025 | 0.017 | 0.05 | 0.34 | 1 |

Note: Special size and specification can be customized.

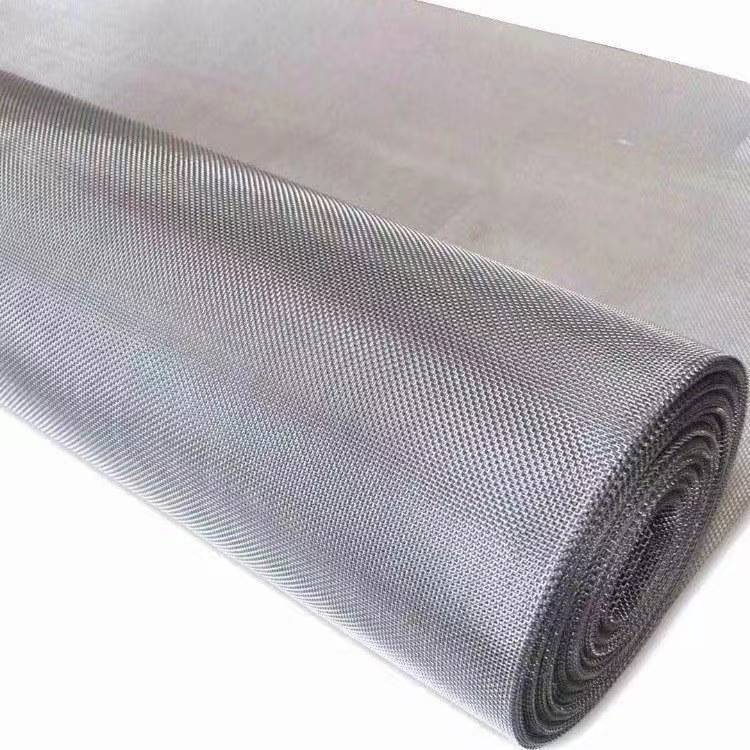

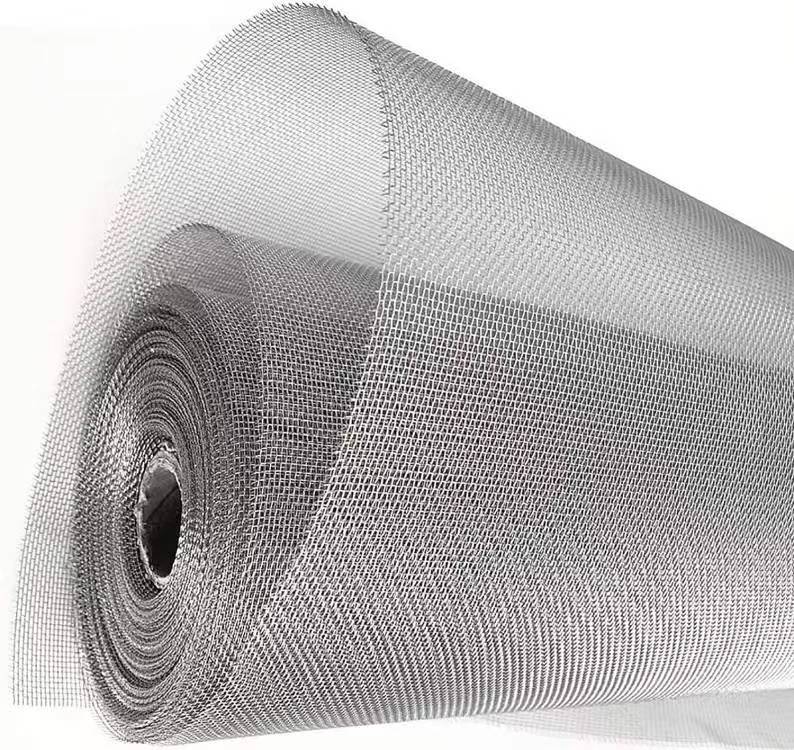

Product Photo Showcase and Alias

Dutch Cloth: Referred to as Dutch Cloth, this variant emphasizes its textile-like fine weaving, mirroring the meticulous craftsmanship of traditional Dutch fabric making. It highlights the precision and intricacy of the weave, making it suitable for applications requiring detailed and fine filtration.

Dense Mesh: Known as Dense Mesh, this name focuses on the tightly packed arrangement of wires, offering a higher density in comparison to standard meshes. This density is crucial for applications needing superior filtration capabilities, particularly in blocking finer particles.

Closely Woven Mesh: Often referred to as Closely Woven Mesh, this term accentuates the tight, close-knit structure of the weave. This characteristic is essential in applications where very fine filtration is needed, as it ensures minimal space between the wires, effectively trapping smaller particles.

Fine Filtration Mesh: Also known as Fine Filtration Mesh, this name highlights its primary use in fine filtration applications. The emphasis here is on the mesh’s ability to filter out extremely small particles, making it an ideal choice in industries where high-level purity and precision are paramount.

Precision Screen Mesh: Referred to as Precision Screen Mesh, this name emphasizes its role in applications requiring high-precision screening. It underscores the mesh’s ability to consistently filter specific particle sizes, crucial in industries where exact separation is critical.

Microfiltration Mesh: Known as Microfiltration Mesh, this term highlights its capability in filtering minute particles. Ideal for microfiltration processes, it caters to sectors needing to separate very fine substances, ensuring a high degree of purity and filtration accuracy.