JD Hardware Wire Mesh Co., Ltd specializes in a range of Titanium wire mesh products, prized for their excellent corrosion resistance, lightweight structure, and non-toxic attributes. Committed to delivering high-quality products, we cater to the diverse needs of our clients with meshes available in specifications from 1 to 100 mesh. Our production process employs various weaving techniques, including plain, twilled, and dense weaves, to meet different industrial requirements.

The intricate process of drawing Titanium wire limits us to a minimum diameter of 0.05 mm. Our meshes are known for forming a strong, inert oxide film on their surfaces when in contact with corrosive substances, enhancing their durability. These meshes are particularly effective in harsh environments, such as seawater, chlorinated solutions, and acidic conditions like nitric and chromic acids, as well as in the presence of metal chlorides and organic salts. Perfectly suited for screening, filtering in acidic and alkaline conditions, and gas-liquid separation, our Titanium wire mesh is designed for specific uses, considering its unique properties of low elongation, strength, and flexibility.

Common Sizes and Customization

Each type of Titanium wire mesh we offer is carefully designed to meet specific industry standards and client requirements, with a focus on quality and precision.

- Material Variants:

Titanium Wire Mesh is available in several grades including TA1, TA2, GR2, GR3, R50250, and Titanium alloys, catering to diverse industry needs.

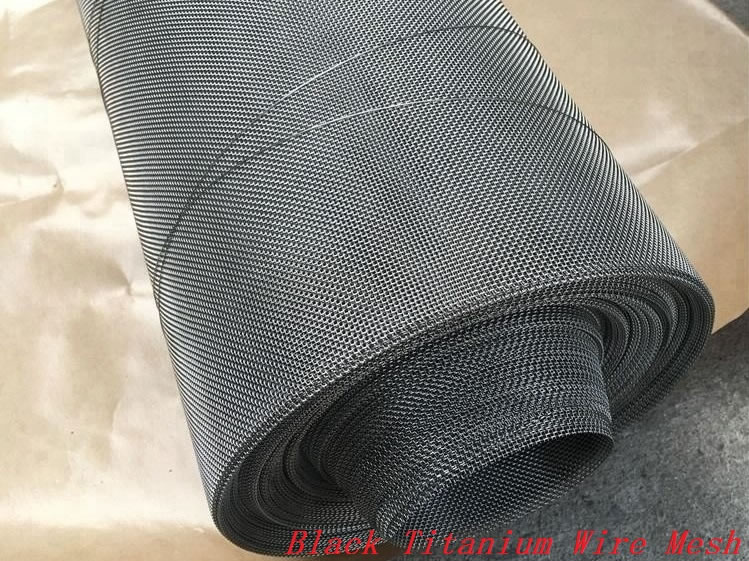

1)Black pure titanium wire (Ti ≥ 99.6%): Ideal for shipbuilding, water filtration, and similar industries.

2)Bright pure titanium wire: Used in electrode production, battery collector nets, and fine chemical filtration.

3)Medical titanium wire: Suitable for creating medical apparatus and instruments. - Wire Diameter and Mesh Details:

The wire diameter ranges from a fine 0.002 mm to 0.035 mm, accommodating a variety of industrial applications. The mesh count varies between 2 and 100, offering flexibility in screening and filtration. - Weaving Techniques:

We offer Plain Weave, Twill Weave, and Dutch Weave, providing options for different strength and permeability requirements. - Dimensions for Specific Needs:

Our Titanium wire mesh is available in widths from 500mm to 2000mm, accommodating large-scale applications. We provide lengths ranging from 1m to 100m, ensuring suitability for various project sizes. - Material Surface Options:

The black surface mesh, containing a graphite coating, is suitable for industries like shipping and water filtration. The light surface mesh, without a graphite coating, is used for more delicate applications such as electrodes, battery nets, and fine filtration.

Size

| Mesh (Wires/ in.) | Wire diameter (in.) | Width of opening (in.) | Open area (%) |

| 4 × 4 | 0.032 | 0.218 | 76 |

| 4 × 4 | 0.035 | 0.215 | 74 |

| 6 × 6 | 0.032 | 0.135 | 65.6 |

| 7 × 7 | 0.025 | 0.118 | 68.2 |

| 8 × 8 | 0.032 | 0.093 | 55.4 |

| 9 × 9 | 0.032 | 0.079 | 50.6 |

| 10 × 10 | 0.035 | 0.065 | 42.3 |

| 10 × 10 | 0.03 | 0.07 | 49 |

| 10 × 10 | 0.025 | 0.075 | 56.3 |

| 12 × 12 | 0.011 | 0.0723 | 75.3 |

| 14 × 14 | 0.016 | 0.055 | 60.2 |

| 16 × 16 | 0.006 | 0.0565 | 81.7 |

| 18 × 18 | 0.01 | 0.046 | 67.4 |

| 18 × 18 | 0.011 | 0.0445 | 64.4 |

| 18 × 18 | 0.016 | 0.04 | 50.8 |

| 20 × 20 | 0.003 | 0.047 | 88.4 |

| 20 × 20 | 0.02 | 0.03 | 36 |

| 20 × 20 TW | 0.016 | 0.034 | 46.2 |

| 24 × 24 | 0.01 | 0.032 | 57.9 |

| 24 × 24 | 0.0118 | 0.0299 | 51.4 |

| 26 × 26 | 0.01 | 0.029 | 54.9 |

| 30 × 30 | 0.01 | 0.0233 | 49 |

| 32 × 32 | 0.01 | 0.021 | 46.5 |

| 35 × 35 | 0.008 | 0.0206 | 51.8 |

| 40 × 40 | 0.005 | 0.02 | 64 |

| 40 × 40 | 0.01 | 0.015 | 36 |

| 50 × 50 | 0.009 | 0.011 | 30.3 |

| 50 × 50 TW | 0.004 | 0.016 | 64 |

| 60 × 60 TW | 0.009 | 0.0077 | 21.3 |

| 90 × 90 | 0.004 | 0.0071 | 41 |

| 100 × 100 | 0.002 | 0.008 | 64 |

| 120 × 120 TW | 0.004 | 0.0043 | 27 |

| 150 × 150 TW | 0.0027 | 0.004 | 35.5 |

| Note: Special size and specification can be customized. | |||

Titanium Wire Mesh Features

- Exceptional Corrosion Resistance: Highly resistant to corrosion, even in harsh environments like seawater and acidic conditions.

- Lightweight and Safe: Low-density, durable, and non-toxic, making it suitable for various applications.

- Protective Oxidation Layer: Forms an inert oxidation film in corrosive environments, enhancing durability.

Versatile in Tough Conditions: Ideal for use in environments with chlorinated solutions, acids, and organic salts.

Applications of Titanium Wire Mesh

- Shipbuilding and Defense Manufacturing: Utilized extensively in marine and military equipment for its strength and corrosion resistance.

- Chemical Industry: Ideal for filters in chemical processing due to its inertness and corrosion resistance.

- Medical Field: Used in medical filtration systems, capitalizing on its non-toxic and biocompatible properties.

- Desalination and Water Treatment: Effective in desalination filters and water treatment systems, resisting saltwater corrosion.

- High-Temperature Equipment: Suitable for use in high-temperature vacuum equipment, maintaining integrity under extreme conditions.

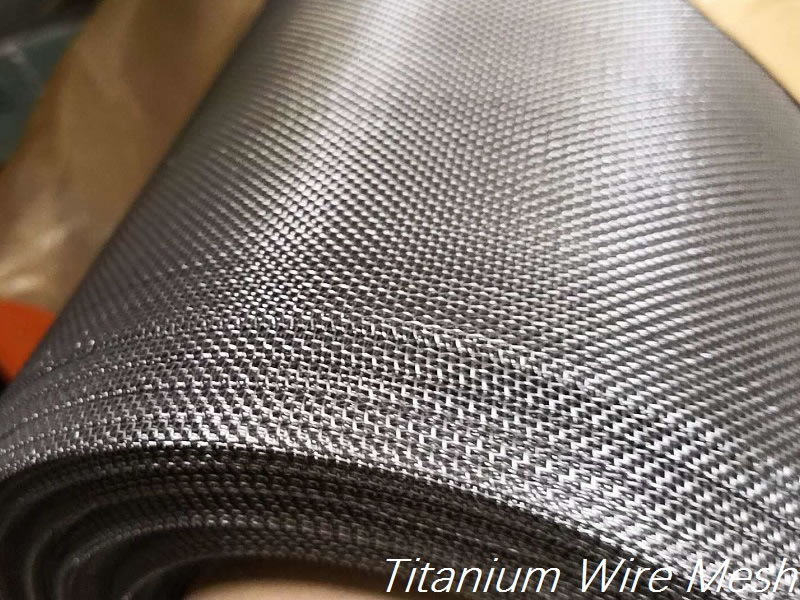

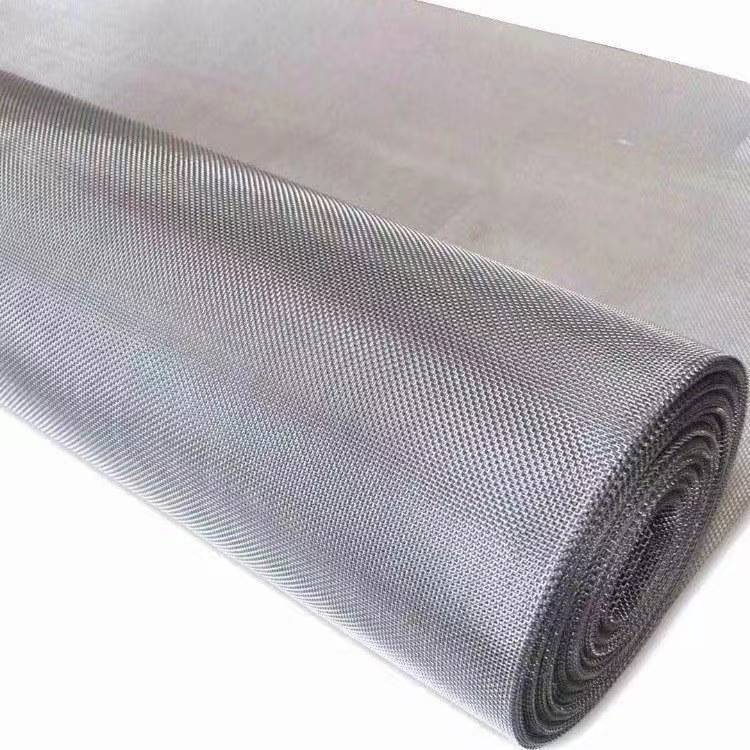

Product Photo Showcase and Alias

Titanium Mesh

Commonly referred to as Titanium Mesh, this material is known for its robustness and lightweight characteristics, often used in applications requiring high corrosion resistance and strength.

Ti Wire Mesh

Ti Wire Mesh, a shorter nomenclature, emphasizes its elemental composition, making it a preferred choice in industries where chemical and physical resilience is paramount.

Titanium Woven Mesh

Titanium Woven Mesh highlights its fabrication method, suggesting its application in scenarios where a specific weave pattern is crucial for filtration and strength.

Titanium Filtration Mesh

As Titanium Filtration Mesh, it is frequently recognized for its use in filtering applications, particularly in the chemical, medical, and water treatment industries due to its non-toxic and corrosion-resistant properties.