JD Hardware Wire Mesh Co., Ltd specializes in the manufacture and export of Super Duplex Stainless Steel Wire Mesh UNS S32750 products. This particular wire mesh, recognized under the designations F53 and SAF2507, boasts a composition of 25% chromium, 4% molybdenum, and 7% nickel and nitrogen. Such a robust blend endows the mesh with outstanding tensile strength and unparalleled corrosion resistance, making it an exemplary choice for demanding environments.

Ideal for use in the chemical and petrochemical industries, as well as in marine applications, this super duplex stainless steel wire mesh stands up to extreme conditions while maintaining integrity and performance. The careful balance of its elemental composition ensures durability and longevity, even in settings exposed to corrosive substances or high salt content. JD Hardware Wire Mesh Co., Ltd is committed to delivering products that meet the highest standards of quality and reliability, tailored to the precise needs of our diverse clientele.

Common Sizes and Customization

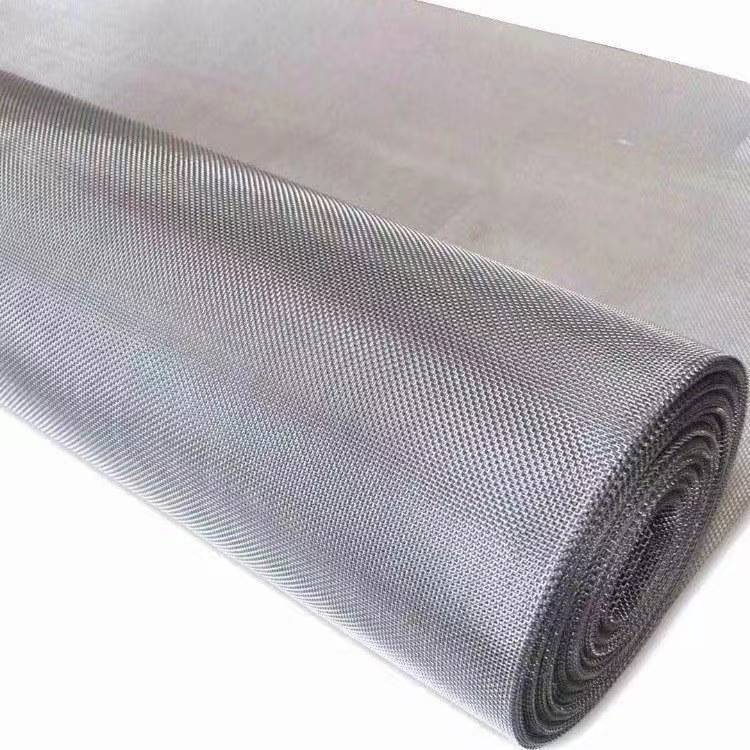

- Material Composition and Weave:

Constructed from Super Duplex Stainless Steel UNS 32750, this wire mesh features a plain weave style, offering robustness and a sleek silver appearance. Its construction ensures optimal performance in challenging environments. - Wire Diameter Range:

The wire mesh is available in diameters ranging from 0.053 mm to 0.6 mm. This spectrum of thicknesses allows for versatile applications, from fine to more robust uses. - Mesh Count Variety:

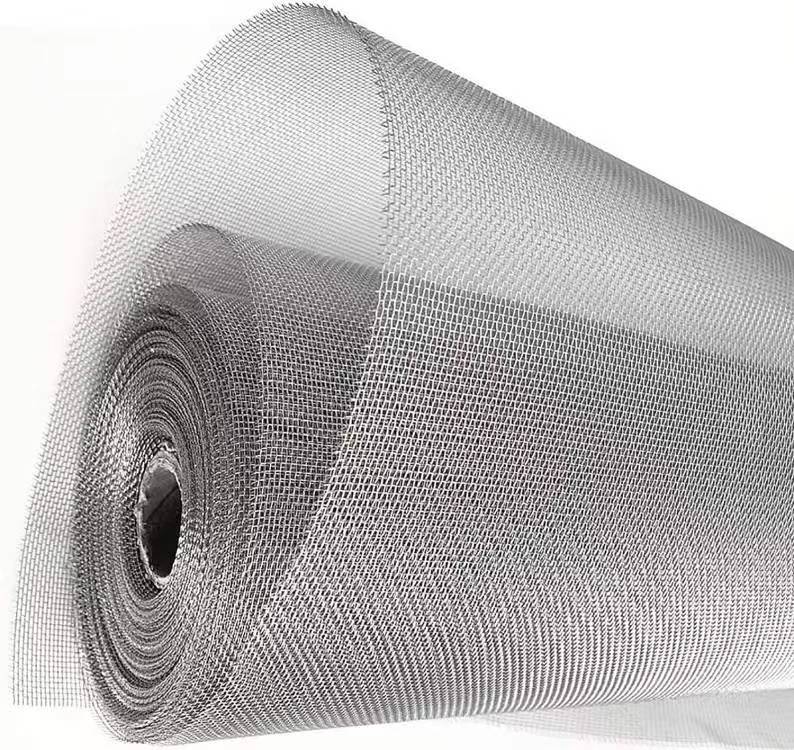

With a mesh count ranging from 2 to 200 MESH, our Super Duplex Stainless Steel Wire Mesh accommodates a wide array of needs, from intricate filtration to broader screening purposes. - Dimensions Tailored to Needs:

Standard widths are 1m, 1.22m, and 1.5m. However, we offer customization to meet specific project requirements. The wire mesh is typically supplied in rolls length of 30 meters, but lengths can be adjusted to cater to the unique demands of each application. - Customization Capabilities:

JD Hardware Wire Mesh Co., Ltd, understand that different projects require specific dimensions. Therefore, our Super Duplex Stainless Steel Wire Mesh UNS 32750 can be customized in both width and length to precisely fit the unique specifications of your project. This flexibility ensures that our clients receive a product that is not only of superior quality but also tailor-made to their specific industrial or commercial needs. Whether it’s for a specialized chemical application or marine use, our wire mesh is designed to deliver exceptional performance. - Chemical Composition

Steel Grade: UNS S32750SAF2507

C: ≤0.03

Mn: ≤1.20

Si ≤0.80

S ≤0.02

P ≤0.035

Cr :24.0-26.0

Ni: 6.0-8.0

Mo: 3.0-5.0

Cu ≤0.5

N: 0.2

| Mesh Count | Wire diameter(mm) | Aperture(mm) | Max width(m) |

| 10 | 0.6 | 1.94 | 1.6 |

| 20 | 0.4 | 0.87 | 1.6 |

| 30 | 0.3 | 0.55 | 1.6 |

| 40 | 0.23 | 0.4 | 1.6 |

| 50 | 0.2 | 0.31 | 1.6 |

| 60 | 0.15 | 0.27 | 1.6 |

| 70 | 0.12 | 0.24 | 1.6 |

| 80 | 0.13 | 0.19 | 1.6 |

| 90 | 0.12 | 0.16 | 1.6 |

| 100 | 0.1 | 0.15 | 1.6 |

| 120 | 0.09 | 0.12 | 1.6 |

| 150 | 0.063 | 0.11 | 1.6 |

| 180 | 0.053 | 0.01 | 1.6 |

| 200 | 0.053 | 0.07 | 1.6 |

Features

- Enhanced Corrosion Resistance:

UNS S32750 stands out for its exceptional resistance to chloride-induced corrosion, owing to its high chromium, molybdenum, and nitrogen content. This alloy outperforms 2205 in extreme corrosion environments, making it ideal for challenging conditions. - Thermal Efficiency:

This wire mesh benefits from high heat conductivity and a low coefficient of thermal expansion, ensuring stability and durability under varying temperature conditions. - Impact Strength and Temperature Limitation:

While it exhibits high impact strength, UNS S32750 is not recommended for use above 299℃, as higher temperatures may reduce its toughness.

Applications

- Oil and Gas Industry: Ideal for harsh offshore and onshore environments, this wire mesh is extensively used in oil and gas equipment and platforms.

- Heat Exchangers and Water Systems: Its suitability for heat exchangers, water treatment equipment, and circulation systems highlights its utility in temperature and corrosion-sensitive applications.

- Chemical and Power Sectors: The mesh is also crucial in the chemical industry, power plants, and for parts requiring high corrosion resistance, demonstrating its versatility across various industrial domains.

Product Also Known As

UNS S32750

UNS S32750 is renowned for its exceptional strength and corrosion resistance, making it ideal for harsh industrial environments. This designation is commonly used in sectors requiring materials that withstand extreme conditions.

SAAF 2507

SAAF 2507 is another name for this robust wire mesh, emphasizing its durability and resistance to corrosion, particularly in marine and chemical applications. This name is often preferred in contexts where material resilience is paramount.

F53

Known as F53 in certain industries, this wire mesh variant highlights its engineering excellence and suitability for high-pressure and corrosive environments, such as in oil and gas extraction.

2507 Super Duplex

As 2507 Super Duplex, this stainless steel wire mesh is recognized for its superior properties in combating pitting and crevice corrosion, making it a reliable choice for demanding applications in chemical processing and desalination plants.