JD Hardware Wire Mesh Co., Ltd offers a range of Pure Nickel Wire Mesh products, crafted from high-purity nickel wire with a minimum purity of 99%. These meshes are characterized by their outstanding resistance to corrosion, acids, and alkalis, making them a robust choice for challenging environments. They are also known for their high electrical and thermal conductivity, along with exceptional ductility, heat, and wear resistance. Our Pure Nickel Wire Mesh is highly sought after in chemical processing industries for its resilience to various chemicals. It’s also widely used in the electronics sector, thanks to its superior electrical conductivity. The mesh’s thermal conductivity and ductility further extend its applicability to heat exchangers, showcasing its versatility across multiple industrial applications.

General Specifications

JD Hardware Wire Mesh Co., Ltd provides Pure Nickel Wire Mesh in a variety of materials, sizes, and customization options to meet diverse industrial needs. Our product range includes:

- Material Options: We offer nickel wire meshes in several grades, including nickel 200, nickel 205, nickel 270, N2, N4, N6, and N8. These materials cater to different application requirements, ensuring both quality and performance.

- Wire Diameter Range: Our meshes are available in wire diameters from as fine as 0.045mm to 0.71mm. This range allows for precise control over mesh properties and end-use functionality.

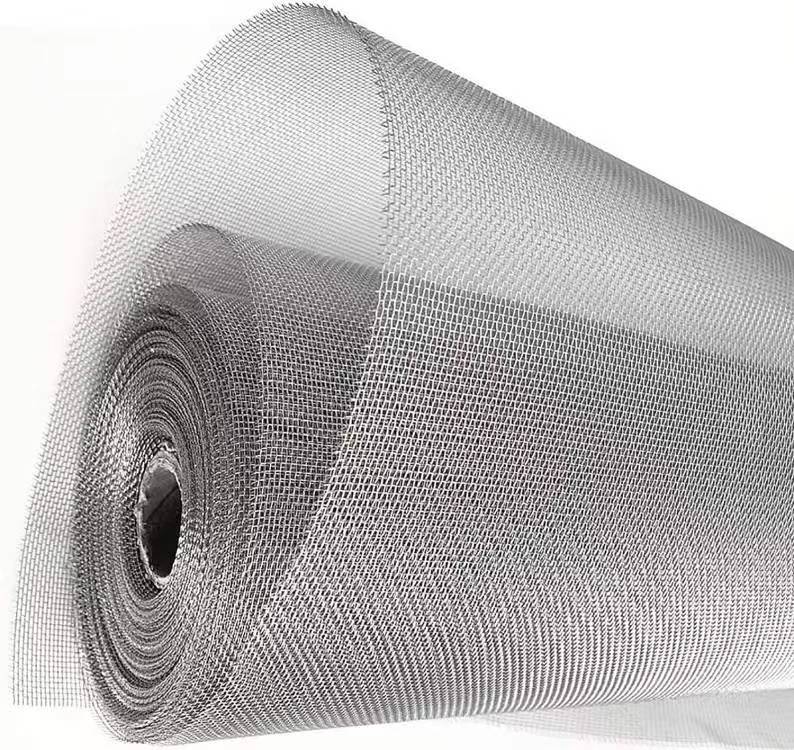

- Mesh Size Variability: Customers can choose from a broad spectrum of mesh sizes, ranging from 8 mesh to 200 mesh. This diversity ensures suitability for various applications, from coarse to fine filtration.

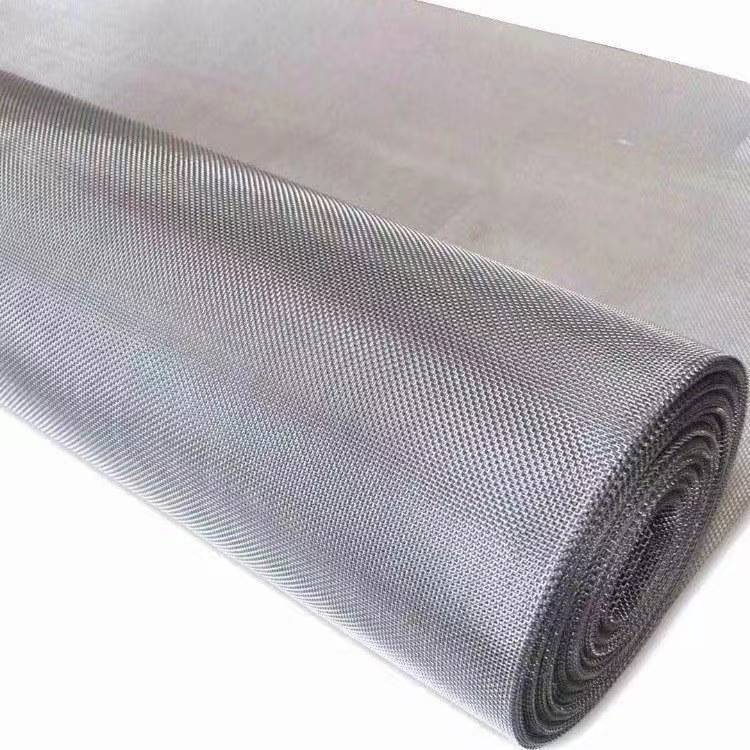

- Weaving Types: To accommodate different structural and functional requirements, we offer three weaving types: plain weave, twill weave, and dutch weave. Each weave type offers unique characteristics and advantages.

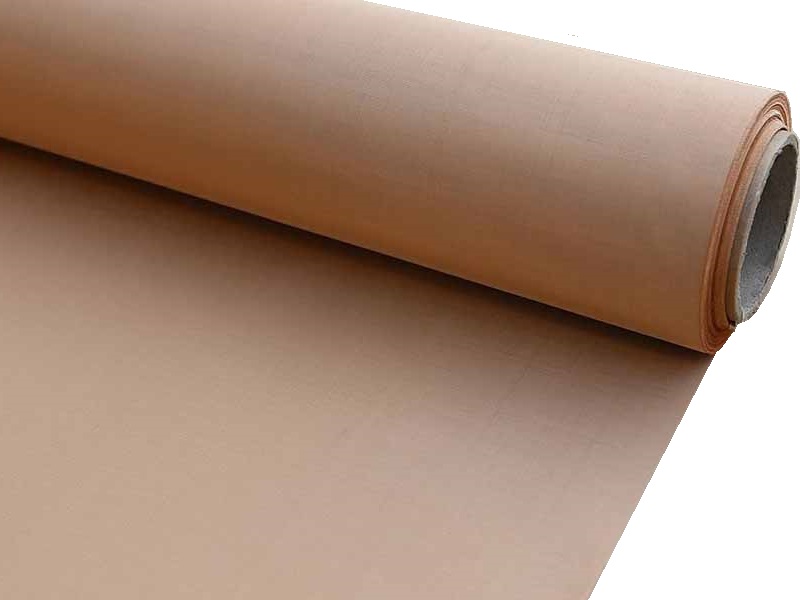

- Natural Color and Aesthetic: All our meshes come in their natural nickel color, providing a clean and professional appearance.

- Standard Widths: Our meshes are available in standard widths of 1m and 1.22m, catering to most common usage scenarios.

- Custom Lengths: Understanding the varied needs of our clients, we offer custom-length options for our nickel wire meshes, ensuring they meet specific project requirements.

Grade Nickel 200 Nickel Wire Mesh

| Mesh count | Wire Diameter (in.) | Type Weave | Width Opening (in.) | Open Area (%) |

| 8 × 8 | 0.028 | Plain | 0.097 | 60.2 |

| 10 × 10 | 0.02 | Plain | 0.08 | 64% |

| 12 × 12 | 0.014 | Plain | 0.0693 | 69.2 |

| 16 × 16 | 0.012 | Plain | 0.0505 | 65.3 |

| 16 × 16 | 0.014 | Plain | 0.0485 | 60.2 |

| 20 × 20 | 0.007 | Plain | 0.043 | 74 |

| 20 × 20 | 0.014 | Plain | 0.036 | 51.8 |

| 25 × 25 | 0.006 | Plain | 0.019 | 57.8 |

| 30 × 30 | 0.013 | Plain | 0.0203 | 37.2 |

| 40 × 40 | 0.006 | Plain | 0.019 | 57.8 |

| 40 × 40 | 0.01 | Plain | 0.015 | 36 |

| 50 × 50 | 0.002 | Plain | 0.018 | 81 |

| 60 × 60 | 0.007 | Plain | 0.0097 | 33.6 |

| 60 × 60 | 0.009 | Twill | 0.0076 | 13.7 |

| 70 × 70 | 0.004 | Plain | 0.0103 | 51.8 |

| 70 × 70 | 0.0045 | Plain | 0.0098 | 46.9 |

| 80 × 80 | 0.0055 | Twill | 0.007 | 31.4 |

| 85 × 70 | 0.006 | Plain | 0 | 28.4 |

| 100 × 100 | 0.004 | Plain | 0.006 | 36 |

| 100 × 100 | 0.0045 | Plain | 0.006 | 30.3 |

| 200 × 200 | 0.0018 | Plain | 0.0032 | 41 |

Grade Nickel 205 Nickel Wire Mesh

| Mesh count | Wire Diameter (in.) | Type Weave | Width Opening (in.) | Open Area (%) |

| 60 × 60 | 0.006 | Plain | 0.0107 | 41 |

Grade Nickel 270 Nickel Wire Mesh

| Mesh count | Wire Diameter (in.) | Type Weave | Width Opening (in.) | Open Area (%) |

| 50 × 50 | 0.067 | plain | 0.0133 | 44.2 |

| 60 × 60 | 0.004 | Plain | 0.0127 | 57.8 |

| 60 × 60 | 0.006 | Plain | 0.0107 | 41 |

| 60 × 60 | 0.007 | Plain | 0.0097 | 33.6 |

| 75 × 75 | 0.006 | Plain | 0.0073 | 30.3 |

| Note: Special size and specification can be customized. | ||||

Chemical Composition of Nickel Wire Mesh

| Grade | C% | Cu% | Fe% | Mn% | Ni% | S% | Si% | Co% | Cr% | Mg% | Ti% |

| Nickel 200 | 0.015 | 0.25 | 0.4 | 0.35 | 99 | 0.01 | 0.35 | — | — | — | — |

| Nickel 205 | 0.02 | 0.001 | 0.005 | 0.001 | 99.97 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 |

| Nickel 270 | 0.15 | 0.15 | 0.2 | 0.35 | 99 | 0.15 | 0.15 | — | 0.01-0.05 | 0.01-0.08 |

| Grade | Ni+Co | Cu | Si | Mn | C | Mg | S | Fe | Impurity Sum |

| Min | Max | ||||||||

| N2 | 9998 | 1 | 3 | 2 | 5 | 3 | 1 | 7 | 2 |

| N4 | 999 | 15 | 3 | 2 | 1 | 1 | 1 | 4 | 1 |

| N6 | 995 | 6 | 10 | 5 | 10 | 10 | 5 | 10 | 5 |

| N8 | 990 | 15 | 15 | 20 | 20 | 10 | 15 | 30 | 10 |

These specifications highlight our commitment to offering versatile, high-quality Pure Nickel Wire Mesh solutions, tailored to the unique demands of each application.

Features of Pure Nickel Wire Mesh

- Resilience to Chemicals: Exhibits a strong resistance to chemicals, including both acids and alkalis, ensuring durability in harsh chemical environments.

- Excellent Electrical Conductivity: Possesses superior electrical conductivity, making it ideal for applications requiring efficient electrical transmission.

- Thermal Conductivity and Flexibility: Offers high thermal conductivity coupled with notable ductility, allowing for effective heat transfer and flexible application.

- Robust Against Corrosion: Designed to withstand corrosive elements, enhancing its longevity and reliability in various settings.

- Heat Tolerance: Capable of resisting high temperatures, which makes it suitable for applications where heat resistance is critical.

- Durability Against Wear: Demonstrates a high level of wear resistance, ensuring sustained performance over time.

Applications of Pure Nickel Wire Mesh

- Corrosion-Prone Environments and Chemical Filtration: Excelling in environments susceptible to corrosion, this mesh is ideal for filtering liquids and gases. Its chemical resistance makes it suitable for a wide range of applications in the chemical industry, handling both acidic and alkaline substances.

- Electrical, Electronic, and EMI Shielding: With high electrical conductivity, Pure Nickel Wire Mesh is essential in electrical and electronic components, especially for EMI shielding.

- Industrial Heat Management: The mesh’s thermal conductivity and heat resistance qualify it for use in heat exchangers and other high-temperature industrial processes.

- Aerospace, Automotive, and Petrochemical Industries: Its durability, resistance to high temperatures, and corrosion make it a preferred material in aerospace, automotive, and petrochemical processing.

- Pharmaceutical and Water Treatment: In pharmaceutical manufacturing and water treatment facilities, the mesh’s ability to withstand various chemicals and its corrosion resistance are highly valued.

- Fuel Cell Technology and Battery Manufacturing: Its porosity and conductivity make it suitable for gas diffusion layers in fuel cells and for use in advanced battery manufacturing.

- Food Processing and Scientific Applications: Non-toxic and chemically resistant, it is used in food processing and for precise filtering in research and laboratory settings.

- Architectural and Decorative Uses: The aesthetic appeal of Pure Nickel Wire Mesh extends its application to architectural and decorative projects.

Product Also Known As

Pure Nickel Wire Mesh

This mesh is renowned for its exceptional corrosion resistance, making it ideal for use in harsh chemical environments. Its purity ensures optimal performance in demanding conditions.

Nickel 200 Wire Mesh

Characterized by its high nickel content, this mesh offers excellent electrical and thermal conductivity, suitable for electrical and thermal applications.

High-Purity Nickel Mesh

Emphasizing its high purity, this mesh is particularly effective in pharmaceutical and food processing industries due to its non-toxic nature and chemical resistance.

Industrial Nickel Mesh

Focused on industrial applications, this mesh is recognized for its strength and resistance to high temperatures, making it ideal for aerospace and automotive industries.