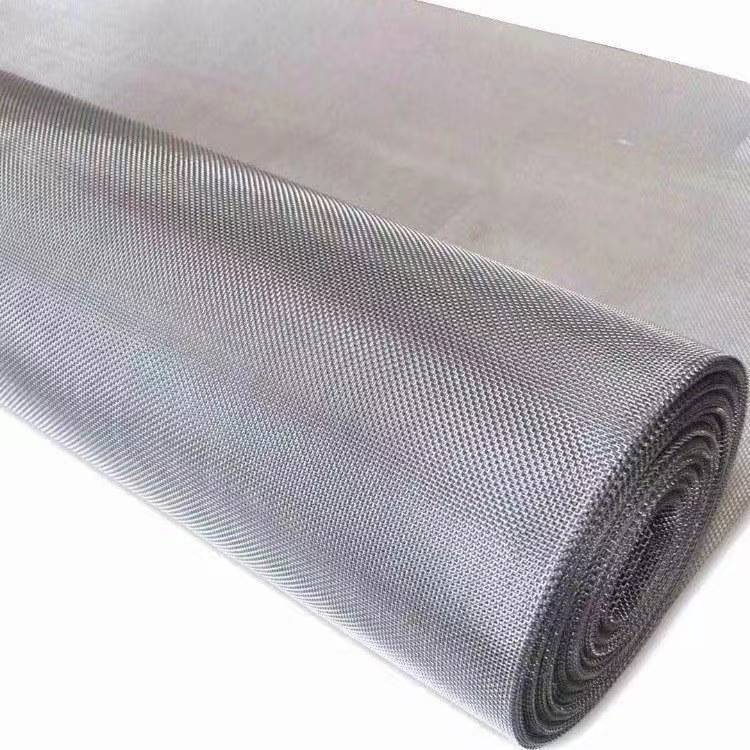

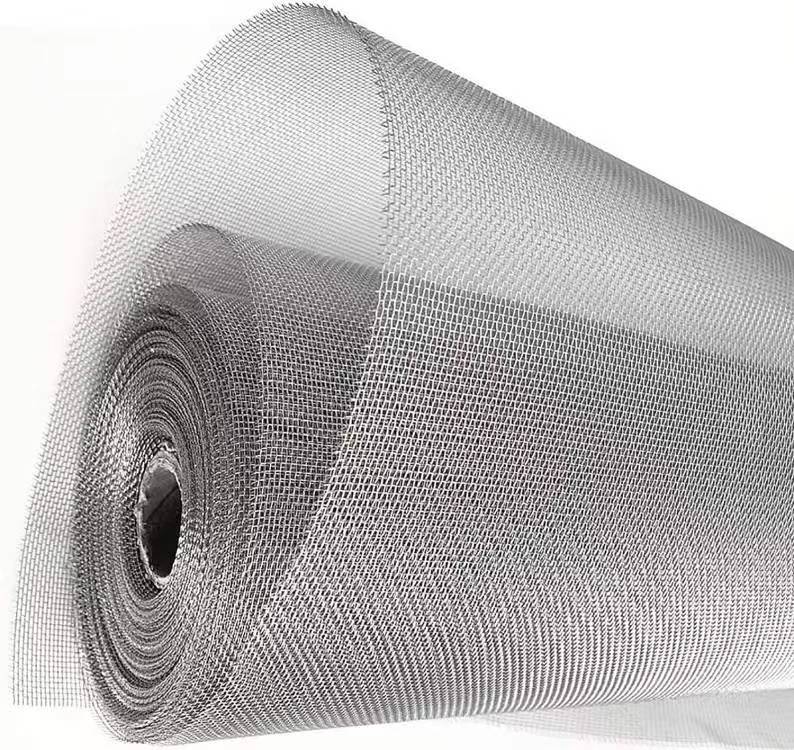

JD Hardware Wire Mesh Co., Ltd specializes in producing and exporting high-quality Inconel wire mesh. Our range, including Inconel 600, 601, 625, 718, and X750, is woven from a durable alloy of nickel, chromium, and iron, tailored to meet specific industry needs. Our Inconel mesh is non-magnetic and withstands temperatures up to 1093°C. With superior corrosion and oxidation resistance compared to standard nickel wire mesh, it’s ideal for challenging environments. Particularly useful in the petrochemical and aerospace industries, our Inconel wire mesh ensures durability and reliability where it matters most.

Inconel Wire Mesh Sizes and Customization Options

These dimensions and material options provide the flexibility to customize Inconel wire mesh according to specific industry requirements, ensuring a perfect fit for any application in the petrochemical, aerospace, or other sectors where durability and resistance are paramount.

- Material Variants:

We offers Inconel wire mesh in various material types to cater to diverse industrial needs. Our range includes:

Inconel 600 (N06600)

Inconel 601 (N06601)

Inconel 625 (N06625)

Inconel 718 (N07718)

Inconel X-750 (N07750) - Mesh Types and Weave Techniques:

We offer Inconel wire mesh in two types – Dutch and Twill – and two weave styles, Plain and Twill, each tailored for specific applications and performance. - Mesh Range:

The mesh count of our Inconel wire mesh varies from 4 to 200mesh, allowing for a wide selection based on the fineness or coarseness required for different applications. - Dimensions:

To accommodate various project scales, our Inconel wire mesh comes in:

Width: Ranging from 1 meter to 2 meters

Length: Available from 1 meter up to 100 meters

Chemical Composition

| Grade | C | Cr | Cu | Fe | Mn | Ni | S | Si | ||||||||

| Inconel 600 | 0.15 | 14 – 17 | 0.5 | 6—10 | 1 | 72 | 0.015 | 0.5 | ||||||||

| Grade | C | Cr | Cu | Fe | Mn | Ni | S | Si | Al | |||||||

| Inconel 601 | 0.1 | 21 – 25 | 1 | Rem | 1 | 58 – 63 | 0.015 | 0.5 | 1.0 – 1.7 | |||||||

| Grade | C | Cr | Fe | Mn | Ni | S | Si | Al | Cb | Mo | P | Ti | ||||

| Inconel 625 | 0.1 | 20 – 23 | 5 | 0.5 | Rem | 0.15 | 0.5 | 0.4 | 3.15 – 4.15 | 8—10 | 0.015 | 0.4 | ||||

| Grade | C | Cr | Cu | Fe | Mn | Ni | S | Si | Al | Cb | Mo | P | Ti | B | C | Co |

| Inconel 718 | 0.08 | 17-21 | 0.3 | Rem | 0.035 | 50 – 55 | 0.015 | 0.35 | 0.2 – 0.8 | 4.75 – 5.50 | 2.8 – 3.3 | 0.015 | 0.65 – 1.15 | 0.006 | 0.08 | 1 |

| Grade | C | Cr | Cu | Fe | Mn | Ni | S | Si | Al | Cb | Ti | |||||

| Inconel 750 | 0.08 | 14 –17 | 0.5 | 5 – 9 | 1 | 70 | 0.01 | 0.5 | 0.4 – 1 | 0.7 – 1.2 | 2.0 – 2.6 |

Size

| Mesh (Wires/ in.) | Wire diameter (in.) | Width of opening (in.) | Open area (%) |

| 4 × 4 | 0.12 | 0.13 | 27 |

| 4 × 4 | 0.08 | 0.17 | 46.2 |

| 4 × 4 | 0.063 | 0.187 | 56 |

| 5 × 5 | 0.04 | 0.16 | 64 |

| 6 × 6 | 0.041 | 0.0126 | 57.2 |

| 8 ×8 | 0.047 | 0.078 | 38.9 |

| 8 × 8 | 0.041 | 0.084 | 45.2 |

| 8 × 8 | 0.03 | 0.095 | 57.8 |

| 8 × 8 | 0.028 | 0.097 | 60.2 |

| 10 × 10 | 0.0225 | 0.075 | 56.3 |

| 10 × 10 | 0.015 | 0.085 | 72.3 |

| 12 × 12 | 0.041 | 0.042 | 25.4 |

| 12 × 12 | 0.025 | 0.058 | 48.4 |

| 16 × 16 | 0.036 | 0.0275 | 19.4 |

| 16 × 16 | 0.028 | 0.035 | 30.5 |

| 16 × 16 | 0.025 | 0.038 | 36 |

| 16 × 16 | 0.023 | 0.04 | 39.9 |

| 16 × 16 | 0.018 | 0.045 | 50.7 |

| 18 × 18 | 0.028 | 0.028 | 24.7 |

| 20 × 20 | 0.016 | 0.034 | 46.2 |

| 22 × 22 | 0.015 | 0.031 | 45 |

| 24 × 24 | 0.014 | 0.028 | 44.2 |

| 24 × 24 | 0.012 | 0.03 | 50.8 |

| 28 × 28 | 0.013 | 0.023 | 40.4 |

| 30 × 30 | 0.015 | 0.018 | 30.1 |

| 30 × 30 | 0.01 | 0.0233 | 48.9 |

| 35 × 35 | 0.0055 | 0.0236 | 68.1 |

| 40 × 40 | 0.01 | 0.015 | 36 |

| 50 × 50 | 0.009 | 0.011 | 30.2 |

| 60 × 60 | 0.0075 | 0.0092 | 30.5 |

| 80 × 80 | 0.0055 | 0.007 | 31.4 |

| 100 × 100 | 0.004 | 0.006 | 36 |

| 100 × 100 | 0.0045 | 0.0055 | 30.2 |

| 120 × 120 | 0.0038 | 0.0046 | 30.7 |

| 120 × 120 | 0.002 | 0.0063 | 57.8 |

| 200 × 200 | 0.0021 | 0.0029 | 33.6 |

| 200 × 200 | 0.002 | 0.003 | 36 |

Features of Inconel Wire Mesh

- Non-Magnetic Nature: Ideal for applications requiring minimal magnetic interference.

- Oxidation Resistance: Maintains integrity even in high-heat environments.

- High-Temperature Resilience: Withstands extreme temperatures without structural compromise.

- Corrosion and Cracking Resistance: Durable in both normal and high-temperature conditions.

- Strong Mechanical Properties: Exhibits robust strength and ductility for heavy-duty use.

- Versatility: Suitable for a wide range of challenging industrial applications.

Applications of Inconel Wire Mesh

- Petrochemical Industry: Essential for operations involving harsh chemicals and high temperatures.

- Aerospace Industry: Used in aircraft components due to its durability and heat resistance.

- Energy Sector: Ideal for hydropower and nuclear power applications, where reliability under extreme conditions is crucial.

- Oil Refining and Shipbuilding: Offers corrosion resistance in marine environments and refining processes.

- Chemical and Machinery Manufacturing: Suitable for machinery parts and chemical processing equipment due to its robust properties.

Product Also Known As

Inconel Wire Mesh:

Inconel Wire Mesh is widely recognized for its exceptional heat and corrosion resistance, making it ideal for extreme environments like aerospace and petrochemical industries.

Nickel-Chromium Iron Alloy Mesh:

Nickel-Chromium Iron Alloy Mesh, essentially Inconel Wire Mesh, excels in environments requiring high-temperature endurance and corrosion resistance, commonly used in advanced engineering fields.

High-Performance Nickel Alloy Mesh:

High-Performance Nickel Alloy Mesh, another term for Inconel Wire Mesh, is known for its durability and resistance to oxidation, serving critical roles in energy and nuclear sectors.

Industrial Grade Inconel Mesh:

Industrial Grade Inconel Mesh, synonymous with Inconel Wire Mesh, is renowned for its strength and resilience under high-pressure conditions, particularly in chemical and marine applications.