JD Hardware Wire Mesh Co., Ltd specializes in producing and exporting Hastelloy wire mesh, a robust nickel-based alloy akin to Monel and nickel-chromium meshes. Comprising nickel, molybdenum, and chromium, our range includes Hastelloy B, C22, C276, and X, each designed to meet specific chemical compositions. Dedicated to offering high-quality, durable, and versatile products, our Hastelloy wire mesh is ideal for various industrial applications, ensuring reliability and longevity in demanding environments.

Our Hastelloy mesh is particularly noted for its excellent corrosion resistance in challenging conditions like acidic, oxidative, and saline environments. The popular Hastelloy B standard mesh exhibits superior resistance to hydrochloric acid across all concentrations and temperatures, maintaining performance even at boiling points and with hydrogen chloride gas. The Hastelloy B-3 mesh further improves upon the B-2 variant, offering reduced cracking and greater chemical stability.

Hastelloy Wire Mesh Sizes and Customization

These detailed specifications underscore our commitment to providing a versatile and comprehensive range of Hastelloy wire mesh products. The combination of varied material options, precise dimensions, and flexible weave types ensures that we can cater to a wide array of industrial requirements, delivering both quality and customization.

- Material Variants: Our Hastelloy wire mesh is available in four material variants: Hastelloy B, C22, C276, and X, each offering unique properties and applications.

Hastelloy B: Known for its resistance to hydrochloric acid at all concentrations and temperatures.

Hastelloy C22: Offers enhanced versatility and resistance to crevice corrosion, pitting, and stress corrosion cracking.

Hastelloy C276: Recognized for its excellent corrosion resistance in severe environments.

Hastelloy X: Stands out for its high strength and oxidation resistance at high temperatures. - Purity Level: All our Hastelloy meshes boast a purity level of over 99.99%, ensuring top-quality material for various industrial uses.

- Mesh Range: Wide range available from finer 6 mesh for small particulate filtration to coarser 200 mesh for larger applications.

- Wire Diameter:

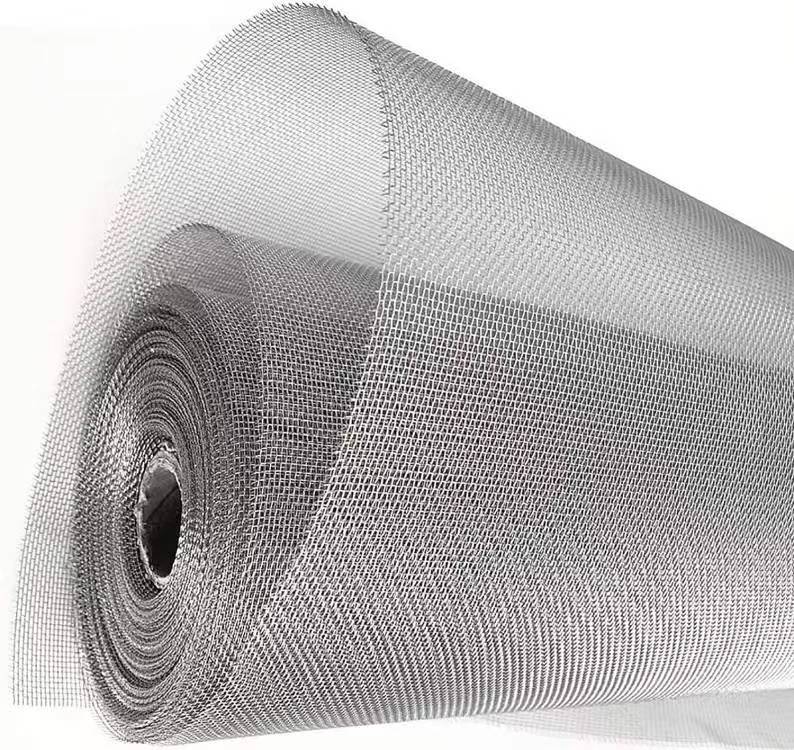

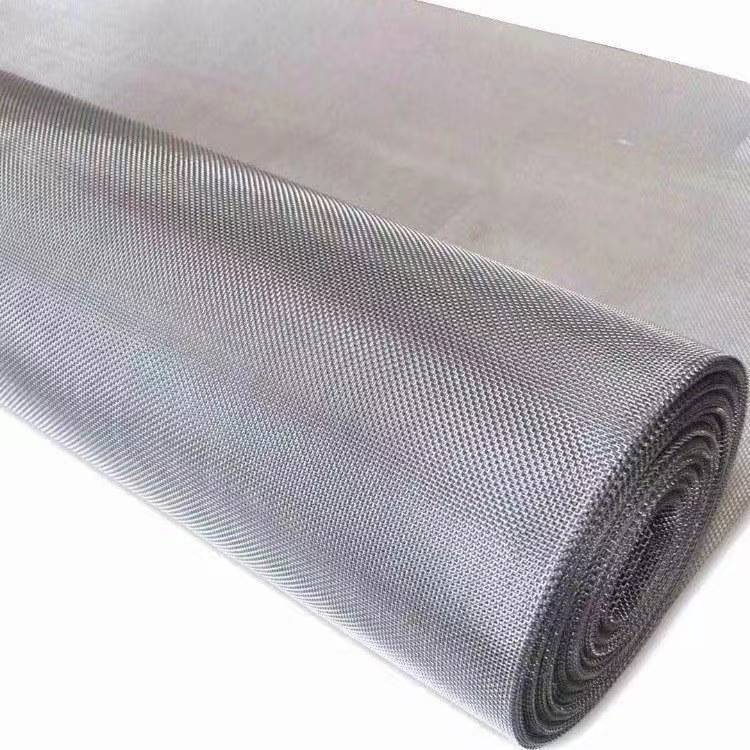

Extensive range from as thin as 0.05 mm for delicate applications to a robust 1.2 mm for more demanding uses. - Weave Types:

Plain Weave: Ideal for standard applications, offering uniformity and strength.

Twill Weave: Provides added strength for heavier loads and is suitable for more complex applications.

Dimensions:

Width Options: Customizable from a narrow 0.1 meters, suitable for small-scale applications, up to a wider 1.5 meters for larger projects.

Length Variability: Ranges from compact lengths of 10 meters to extensive lengths of 100 meters, accommodating both small-scale tasks and large industrial projects.

Chemical Composition

| Type | C | Co | Cr | Cu | Fe | Mn | Mo | Ni | P | S | Si | Sn | V | W |

| H-B | 0.12 | 2.5 | 1 | – | 6 | 1 | 26.0-30.0 | Rem | 0.01 | – | 0.03 | – | 0.6 | – |

| H-C22 | 0.015 | 2.5 | 14.5 – 20.0 | – | 2.0-6.0 | 0.5 | 12.8-14.5 | Rem | – | 0.02 | 0.08 | – | 0.35 | – |

| H-C276 | 0.02 | 2.5 | 14.5 – 16.5 | – | 4.0-7.0 | 1 | 15.0-17.0 | Rem | 0.03 | 0.03 | 0.08 | – | 0.35 | 3.0 – 4.5 |

| H-X | 0.08 | – | 17.0 – 20.0 | 1 | Rem | 2 | – | 34.0-37.0 | 0.03 | 0.03 | 0.75- .50 | 0.025 | – | – |

Specifications of Hastelloy B wire mesh

| Mesh (Wires/ in.) | Wire diameter (in.) | Width of opening (in.) | Open area (%) |

| 16 × 16 | 0.014 | 0.049 | 60.2 |

| 30 × 30 | 0.0085 | 0.025 | 55.4 |

| 30 × 30 | 0.0106 | 0.0227 | 46.5 |

| 60 × 60 | 0.0072 | 0.009 | 30.5 |

| 200 × 200 | 0.002 | 0.003 | 36 |

Specifications of Hastelloy C276 wire mesh

| Mesh (Wires/ in.) | Wire diameter (in.) | Width of opening (in.) | Open area (%) |

| 6 × 6 | 0.047 | 0.12 | 51.8 |

| 8 × 8 | 0.032 | 0.093 | 55.4 |

| 10 × 10 | 0.025 | 0.075 | 56.3 |

| 12 × 12 | 0.023 | 0.06 | 51.8 |

| 12 × 12 | 0.016 | 0.067 | 64.5 |

| 12 × 12 | 0.015 | 0.068 | 66.6 |

| 14 × 14 | 0.02 | 0.051 | 51 |

| 16 × 16 | 0.018 | 0.045 | 50.7 |

| 16 × 16 | 0.009 | 0.0535 | 73.27 |

| 20 × 20 | 0.023 | 0.027 | 29.2 |

| 20 × 20 | 0.016 | 0.034 | 46.2 |

| 20 × 20 | 0.009 | 0.041 | 67.2 |

| 24 × 24 | 0.014 | 0.028 | 44.2 |

| 30 × 30 | 0.013 | 0.02 | 37.1 |

| 30 × 30 | 0.009 | 0.024 | 53.1 |

| 40 × 40 | 0.01 | 0.015 | 36 |

| 40 × 40 | 0.009 | 0.016 | 41 |

| 40 × 40 | 0.0075 | 0.018 | 49 |

| 50 × 50 | 0.009 | 0.011 | 30.3 |

| 60 × 60 | 0.0072 | 0.009 | 30.5 |

| 60 × 60 | 0.0044 | 0.0123 | 54.2 |

| 80 × 80 | 0.007 | 0.006 | 19.4 |

| 80 × 80 | 0.001 | 0.0085 | 46.2 |

| 100 × 100 | 0.001 | 0.006 | 36 |

| 120 × 120 | 0.004 | 0.0043 | 27 |

| 180 × 180 | 0.002 | 0.0036 | 41 |

| 200 × 200 | 0.0023 | 0.0027 | 48 |

| 200 × 200 | 0.002 | 0.003 | 36 |

Specifications of Hastelloy X wire mesh

| Mesh (Wires/ in.) | Wire diameter (in.) | Width of opening (in.) | Open area (%) |

| 10 × 10 | 0.025 | 0.075 | 56.3 |

| 18 × 18 | 0.009 | 0.047 | 70.4 |

| 20 × 20 | 0.016 | 0.034 | 46.2 |

| 50 × 50 | 0.003 | 0.017 | 72.3 |

| 60 × 60 | 0.0075 | 0.009 | 30.5 |

| Note: Special size and specification can be customized. | |||

Features of Hastelloy Wire Mesh

- Corrosion Resistance: Hastelloy mesh is exceptionally resistant to corrosion, ensuring durability even in harsh environments.

- Acid and Alkali Endurance: Its robustness against acidic and alkaline substances makes it suitable for challenging chemical exposures.

- High-Temperature Tolerance: This mesh can withstand extreme temperatures, maintaining integrity in high-heat applications.

- Salt Resistance: Its ability to resist salt corrosion makes it ideal for marine and coastal applications.

- Chemical Stability: The mesh remains stable under various chemical reactions, ensuring long-term reliability.

- Superior Filtering Quality: Hastelloy wire mesh provides excellent filtration performance, making it effective in precision separation processes.

Applications of Hastelloy Wire Mesh

- Chemical Industry: Used extensively for its resistance to harsh chemicals and acids, making it ideal for chemical processing.

- Petrochemical Sector: Its durability in high-temperature and corrosive environments suits petrochemical processing.

- Flue Gas Desulfurization: Effective in controlling emissions, it’s vital in reducing environmental pollution.

- Pulp and Paper Industry: Withstands the corrosive substances used in pulp and paper manufacturing.

- Environmental Protection: Plays a crucial role in pollution control equipment, aiding in environmental conservation efforts.

Product Also Known As

Hastelloy Wire Mesh:

Commonly used in the chemical industry for its corrosion resistance, especially in environments with acidic and alkaline substances. It’s also utilized in water treatment plants for its ability to withstand harsh, corrosive conditions.

Hastelloy Alloy Mesh:

Frequently applied in the petrochemical sector, this mesh excels in high-temperature and corrosive environments, making it suitable for refining processes. It’s also used in the aerospace industry for its high strength and temperature resistance.

Nickel-Molybdenum-Chromium Mesh:

Ideal for use in the pharmaceutical industry, where chemical stability and resistance to contamination are crucial. It’s also used in the food processing industry for its non-reactive qualities and ability to maintain purity.

Hastelloy Industrial Mesh:

Widely used in environmental protection applications, particularly in pollution control equipment. It’s also employed in the pulp and paper industry, resisting the corrosive substances used in paper processing.