JD Hardware Wire Mesh Co., Ltd specializes in the manufacture and export of copper wire mesh products, offering a diverse range of applications due to the inherent properties of copper and its alloys. Our copper wire mesh, recognized for its ductility, malleability, and superior thermal and electrical conductivity, serves a wide array of industries and purposes. These include, but are not limited to, RFI shielding, construction of Faraday cages, innovative roofing solutions, HVAC system components, and an assortment of electrical applications.

Our copper wire mesh, though softer compared to stainless steel alternatives, boasts remarkable durability and an inherent resistance to atmospheric corrosion. This resilience, however, does not extend to certain oxidizing agents such as nitric acid, ferric chloride, cyanides, and ammonia acid compounds, which can affect the mesh. In compliance with ASTM E-2016-11, a recognized industry standard, our products are crafted from 99.9% pure copper. This not only ensures quality and reliability but also leads to the natural formation of a thin, protective green patina over time when exposed to the elements. This unique characteristic enhances the aesthetic appeal while maintaining the functionality of the mesh.

JD Hardware Wire Mesh Co., Ltd is committed to providing high-quality copper wire mesh products that meet the evolving needs of our customers, ensuring satisfaction and utility in a variety of settings.

General specifications

- Wire Diameter: The diameter of the copper wire used in the mesh can range from very fine, such as 0.025 mm, to thicker gauges like 2 mm, catering to different durability and flexibility requirements.

- Mesh Count: This can vary significantly based on the application. Common mesh counts range from 16 wires per inch (coarser mesh) to as high as 200 wires per inch (finer mesh).

- Open Area Percentage: Typical values might range from 30% for finer meshes (higher mesh counts) to 70% for coarser meshes, affecting transparency and screening capabilities.

- Weave Type Customization: Copper wire mesh is available in various weave types. While the plain weave is standard, twill and Dutch weaves can be customized according to specific application needs.

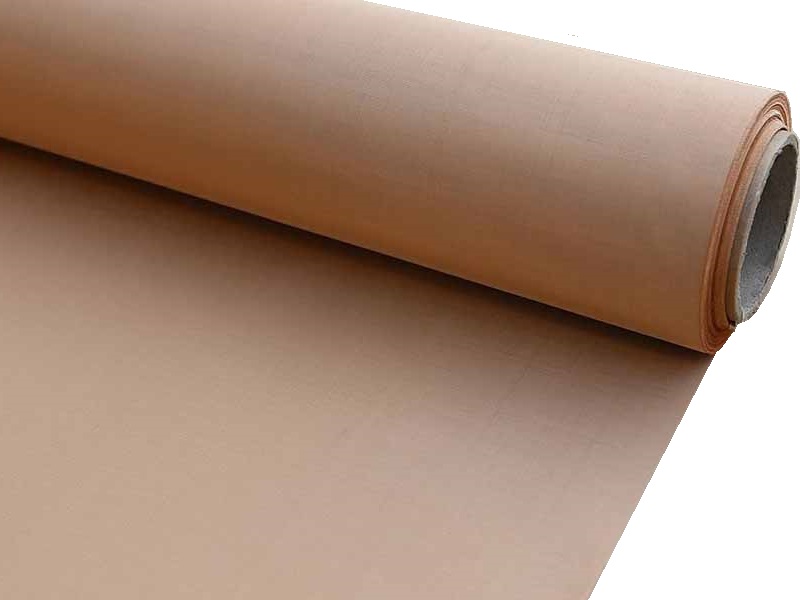

- Dimensions and Shape: Copper wire mesh can be cut and shaped to custom dimensions, accommodating diverse applications. Rolls can be provided in widths ranging from 1 inch to 48 inches, and lengths as required by the project.

- Finish and Treatment: Beyond the natural sheen, treatments can be applied for additional corrosion resistance or to hasten the development of a patina for aesthetic purposes.

- Compliance with Standards: Custom orders can be made to comply with specific industry standards beyond ASTM E-2016-11, depending on the application’s regulatory requirements.

Types of Copper Wire Mesh

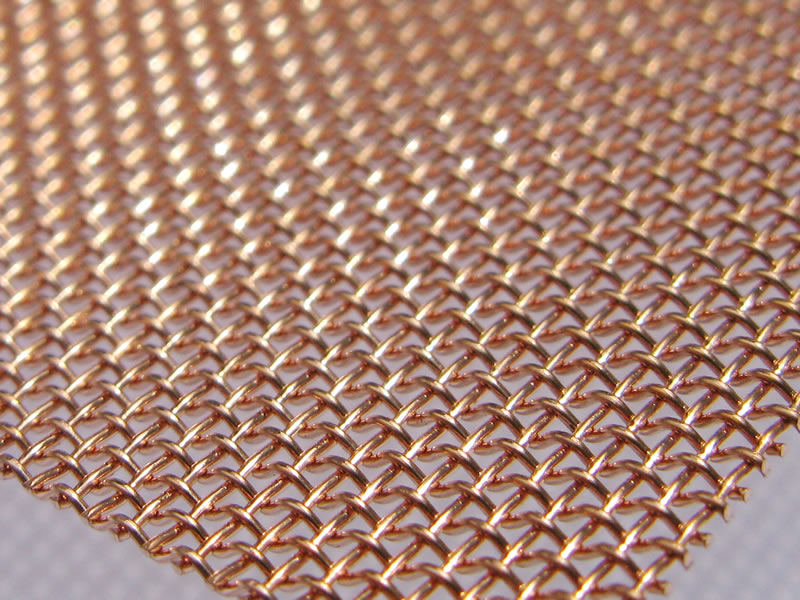

- Plain Weave Copper Mesh: Plain weave copper mesh, characterized by its simple over-and-under weaving pattern, is the most common and versatile type. Each weft wire crosses alternately above and below each warp wire, creating a uniform and square opening. This mesh is typically used for general screening and filtration applications. Its balanced structure offers a combination of good strength and open area, making it suitable for various industrial, architectural, and design uses. Plain weave mesh is often chosen for its ease of handling and consistency in performance.

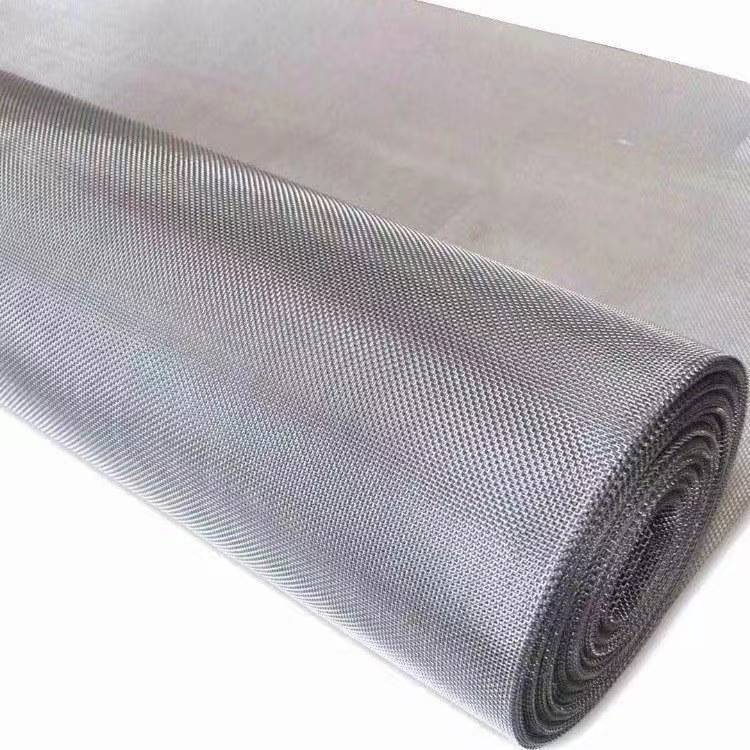

- Twill Weave Copper Mesh: Twill weave copper mesh is distinguished by each weft wire passing over and under two warp wires in a staggered manner. This creates a diagonal pattern and allows for the use of heavier wires and tighter mesh openings. Twill weave provides enhanced strength and is ideal for applications requiring finer filtration. It’s often utilized in industrial processes where durability and filtration precision are key. The unique structure of twill weave mesh makes it more pliable and suitable for applications where a sturdier mesh is required.

- Dutch Weave Copper Mesh: Dutch weave copper mesh is known for its fine filtration capabilities. The weave pattern involves a tight, dense arrangement of thinner warp wires and thicker weft wires. This configuration results in smaller openings and higher filtration accuracy, making Dutch weave mesh ideal for demanding filtration processes in the petrochemical and pharmaceutical industries. The structure is robust and offers excellent strength and stability, ensuring long-lasting performance in high-pressure environments. Dutch weave mesh is the go-to option for precision filtering needs.

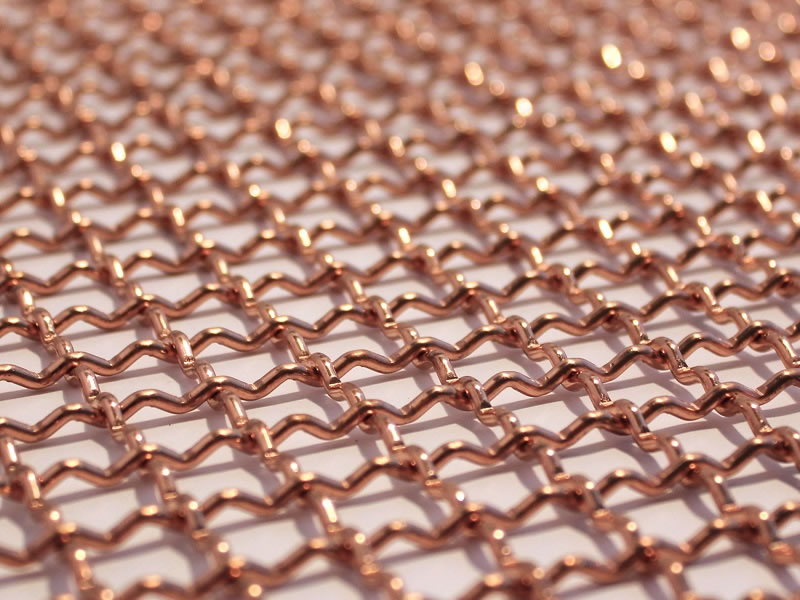

- Crimped Copper Mesh: Crimped copper mesh features wires that have been pre-crimped before weaving, creating a rigid and stable structure. The crimping process allows for larger openings and increases the structural integrity of the mesh. This type is mainly used in architectural and decorative applications, offering both aesthetic appeal and functionality. The unique texture of crimped mesh adds visual interest and is often employed in façade cladding, interior design, and garden landscaping. It’s also used for protective screens, offering a balance of visibility and security.

- Knitted Copper Mesh: Knitted copper mesh, made by interlocking loops of wire, is known for its exceptional flexibility and stretchability. This mesh type is ideal for applications requiring adaptability and moldability, such as RFI shielding, gaskets, and even pest control. The knitting process creates a mesh that can conform to various shapes and absorb vibrations, making it useful in automotive and aerospace industries. Knitted mesh is also used in filtration, where its ability to trap particles while maintaining airflow is beneficial.

- Expanded Copper Mesh: Expanded copper mesh is produced by slitting and stretching solid copper sheets, creating a distinctive diamond-shaped pattern. This process results in a rigid and strong mesh, often used for outdoor architectural elements, security barriers, and various industrial applications. The expanded mesh offers excellent strength-to-weight ratio and good ventilation, making it ideal for protective screens, walkways, and ventilation grilles. Its aesthetic appeal also lends itself to decorative uses in building facades and interior design.

Characteristics

- High Conductivity: Excellent for electrical and thermal applications.

- Corrosion Resistance: Good against atmospheric corrosion but can patina and is less resistant to acids.

- Malleability and Ductility: Easily shaped and cut, versatile for various uses.

- RFI Shielding: Effective in blocking radio frequency interference.

- Aesthetic Appeal: Distinctive reddish-orange color, used for decorative purposes.

- Versatility: Suitable for a wide range of applications, including filtration and screening.

- Strength: Offers a balance of flexibility and durability.

- Heat Transfer: Great for applications needing efficient heat distribution.

Application

- RFI Shielding: Its excellent electrical conductivity makes it ideal for shielding against radio frequency interference, commonly used in electronic equipment enclosures.

- Filtration and Separation: The fine weaves of copper mesh are perfect for filtration processes in the chemical, food, and pharmaceutical industries.

- Architectural and Interior Design: Copper mesh is used for decorative purposes in building facades, room dividers, and artistic installations due to its aesthetic appeal.

- Electrical Applications: Due to its high electrical conductivity, it’s used in electrical grounding and certain types of batteries.

- Automotive and Aerospace: For its thermal conductivity, it’s used in applications requiring heat dissipation.

- Industrial Sifting and Screening: Employed in industries for sifting and screening processes due to its strength and corrosion resistance.

Product Photo Showcase and Alias

Copper Wire Mesh: Used in RFI shielding, electrical grounding, filtration, architectural design, and as a gardening barrier against pests.

Copper Alloy Mesh: Employed in marine environments, industrial filtration, chemical processing, and architectural applications for its enhanced strength and corrosion resistance.

Crimped Copper Mesh: Utilized in architectural designs for facades and wall cladding, and in industrial settings for screening and protective barriers.

Knitted Copper Mesh: Ideal for gaskets, seals, RFI shielding in electronics, industrial filtering, and as a pest control material against rodents and insects.