JD Hardware Wire Mesh Co., Ltd specializes in the manufacture and export of Sintered Metal Fiber Felt, a versatile porous material essential in numerous industrial applications. Our production process involves the meticulous compression and sintering of metal fibers, a technique that bonds the fibers together below their melting point, forming a cohesive structure with interconnected pores.

Our Sintered Metal Fiber Felt is primarily crafted from a diverse range of metals, including but not limited to stainless steel, bronze, and nickel, as well as various specialized alloys. The selection of these materials is carefully tailored to meet the specific requirements of the final product. This customization ensures optimal performance characteristics such as superior corrosion resistance, enhanced temperature endurance, and excellent chemical compatibility.

JD Hardware Wire Mesh Co., Ltd is dedicated to providing solutions that meet the intricate and diverse needs of our clients, leveraging our expertise in sintered metal fiber technology to deliver products that excel in both quality and performance.

Material Composition

Sintered metal fiber felts are crafted from a variety of metal fibers, tailored to meet specific application needs. Key materials include:

- Stainless Steel: Predominantly used for its corrosion resistance and durability, common grades like 316L, 316, and 304 are chosen for their ability to endure chemical exposure and high temperatures.

- Pure Nickel: Selected for applications demanding superior corrosion resistance, especially in extreme chemical or temperature conditions.

- Bronze: Known for its mechanical strength, thermal conductivity, and corrosion resistance, bronze is favored where stainless steel isn’t suitable, particularly in highly acidic or alkaline settings.

- Inconel: A nickel-chromium-based superalloy, Inconel is renowned for its exceptional high-temperature, oxidation, and corrosion resistance, making it ideal for aerospace and high-temperature applications.

- Hastelloy: This nickel-based superalloy is recognized for its extraordinary corrosion resistance in environments with acids, chlorides, and other aggressive substances.

- Copper: Utilized in scenarios requiring good electrical and thermal conductivity.

- Titanium: Noted for its excellent corrosion resistance and lightweight properties, titanium is often employed in aerospace or marine environments where weight is crucial.

Filter Fineness of Sintered Metal Felts

- Range of Filter Ratings:

Sintered metal felts offer a comprehensive spectrum of filter ratings to cater to diverse filtration needs, ranging from coarse to fine grades. Typical filter ratings available include 1 micron, 5 microns, 10 microns, 20 microns, and beyond. - Customization for Specialized Applications:

For more specialized applications requiring finer filtration, manufacturers are equipped to provide custom solutions. These tailored options are designed to meet specific filtration efficiency levels as per the unique requirements of the application.

Specifications of Stainless Steel Sintered Felt

- Absolute Rating:

The absolute ratings for Stainless Steel Sintered Felt typically range from ultra-fine levels such as 1 μm, extending up to coarser ratings like 25 μm. This range ensures versatility in filtration applications, accommodating various degrees of precision. - Bubble Point Pressure:

The bubble point pressure of these felts varies according to their pore size, usually falling within the range of 630 to 12300 Pa. This parameter is crucial for determining the maximum pore size and thereby the filtration capability of the felt. - Average Air Permeability:

The average air permeability of Stainless Steel Sintered Felt is measured in a range that generally spans from 9 to 1000 l/dm²/min. This measure indicates the ease with which air passes through the felt, a critical factor in applications requiring good airflow. - Thickness:

The thickness of the sintered felt is an important specification, typically ranging from 0.32 mm to 0.7 mm. This thickness is instrumental in providing adequate filtration while maintaining structural integrity. - Weight:

The weight of these felts is another key factor, usually lying in the range of 600 to 1200 g/m². This weight contributes to the felt’s durability and effectiveness in various filtration applications. - Porosity:

Porosity percentages in Stainless Steel Sintered Felt typically vary between 65% to 87%. Higher porosity indicates a greater void space in the material, which can impact filtration efficiency and dirt holding capacity. - Dirt Holding Capacity:

Dirt holding capacity is a vital aspect, with common values ranging from 5.47 to 33.97 mg/cm². This metric reflects the amount of particulate matter the felt can retain before requiring cleaning or replacement. - Size:

| Model No. | Absolute Rating, μm | Bubble Point Pressure, Pa | Average Air Permeability, l/dm2/min | Thickness, mm | Weight, g/m2 | Porosity, % | Dirt Holding Capacity, mg/cm2 |

| JDSFF3 | 3 | 12300 | 9 | 0.35 | 975 | 65 | 6.4 |

| JDSFF5 | 5 | 7600 | 34 | 0.34 | 600 | 78 | 5.47 |

| JDSFF7 | 7 | 5045 | 57 | 0.27 | 600 | 72 | 6.47 |

| JDSFF10 | 10 | 3700 | 100 | 0.32 | 600 | 77 | 7.56 |

| JDSFF15 | 15 | 2470 | 175 | 0.37 | 600 | 80 | 7.92 |

| JDSFF20 | 20 | 1850 | 255 | 0.49 | 750 | 81 | 12.44 |

| JDSFF25 | 25 | 1480 | 320 | 0.61 | 1050 | 79 | 19.38 |

| JDSFF30 | 30 | 1235 | 455 | 0.63 | 1050 | 79 | 23.07 |

| JDSFF40 | 40 | 925 | 580 | 0.66 | 1200 | 77 | 25.96 |

| JDSFF60 | 60 | 630 | 1000 | 0.7 | 750 | 87 | 33.97 |

Characteristics of Sintered Metal Fiber Felt

- Elevated Porosity Levels: Ranging from 70% to 95%, the sintered metal fiber felt facilitates superior filtration and fluid distribution, all while minimizing pressure loss.

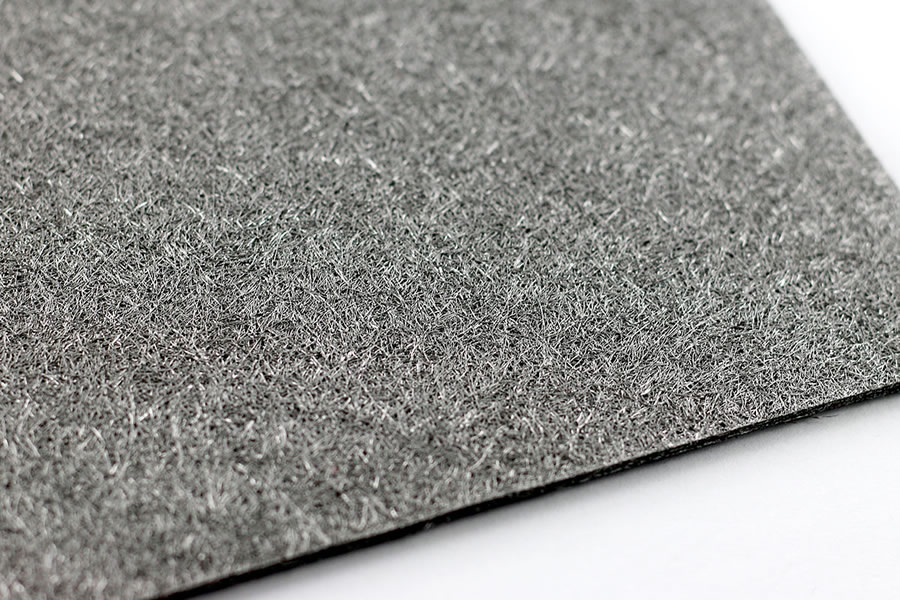

- Network of Interlinked Pores: Resulting from the sintering technique, this felt features a three-dimensional web of interconnected pores, enhancing the movement of fluids and gases.

- Consistent Pore Distribution: Uniformity in pore size throughout the felt is a hallmark of its manufacturing, leading to dependable filtration efficiency and performance.

- Adaptability to Temperature Extremes: Tailored through material selection, certain variants of this felt are capable of enduring exceptionally high temperatures.

- Resistance to Chemicals: The careful choice of metal fibers ensures suitability for use with a broad range of corrosive agents.

- Optimal Filtration Capability: The felt’s finely-sized and uniform pores excel in effectively trapping and holding solid particles, marking it as a highly efficient filter medium.

- Structural Strength in Porous Form: Despite its porous nature, the sintered metal fiber felt exhibits substantial mechanical robustness, equipping it to withstand significant pressure and mechanical forces.

Uses of Sintered Metal Fiber Felt

- Filtration Capabilities: This felt is crucial in diverse filtration tasks. It’s widely employed in refining oil and gas, purifying air and gases, and in liquid filtration processes in the chemical and pharmaceutical sectors.

- Catalytic Efficiency: Given its expansive surface area and porous makeup, it’s excellently suited for catalysis in chemical reactors and systems treating exhaust gases.

- Thermal and Mass Exchange: Its porous nature with interconnected pores enhances its role in heat exchangers, promoting effective thermal and mass transfer across fluids.

- Uniform Fluid Dispersion: The felt’s evenly spread pores facilitate consistent fluid distribution, crucial in fuel cell technology and for streamlining flow in industrial processes.

- Acoustic and Vibration Attenuation: Its ability to absorb sound and vibrations makes it an asset in noise and vibration control, especially in the automotive and aerospace industries.

- Advancement in Battery Technology: In cutting-edge battery models, this felt is pivotal as both a current collector and separator, boosting battery functionality and lifespan.

- Endurance in High Temperatures: The felt is particularly valuable in environments demanding filtration and fluid management at elevated temperatures, serving industries that operate under such intense conditions.

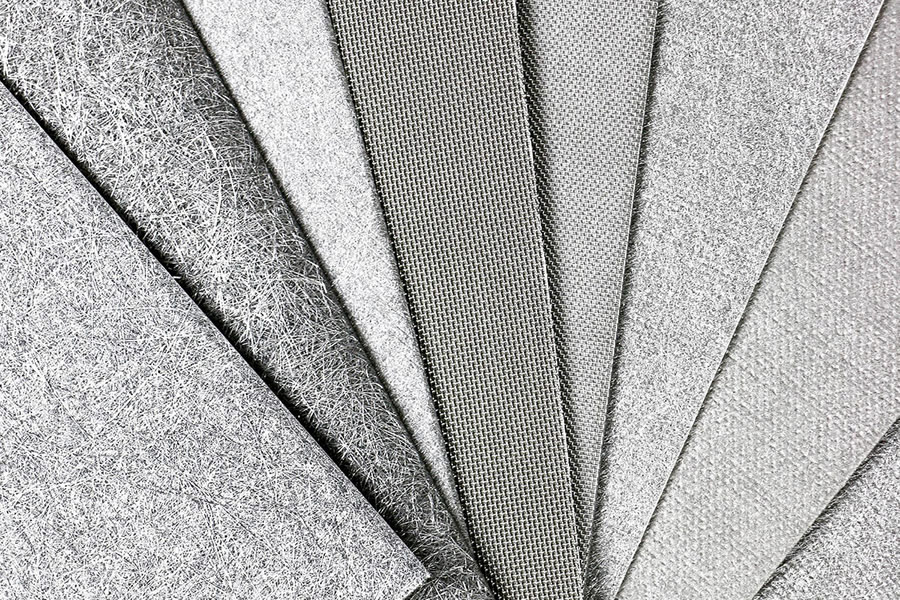

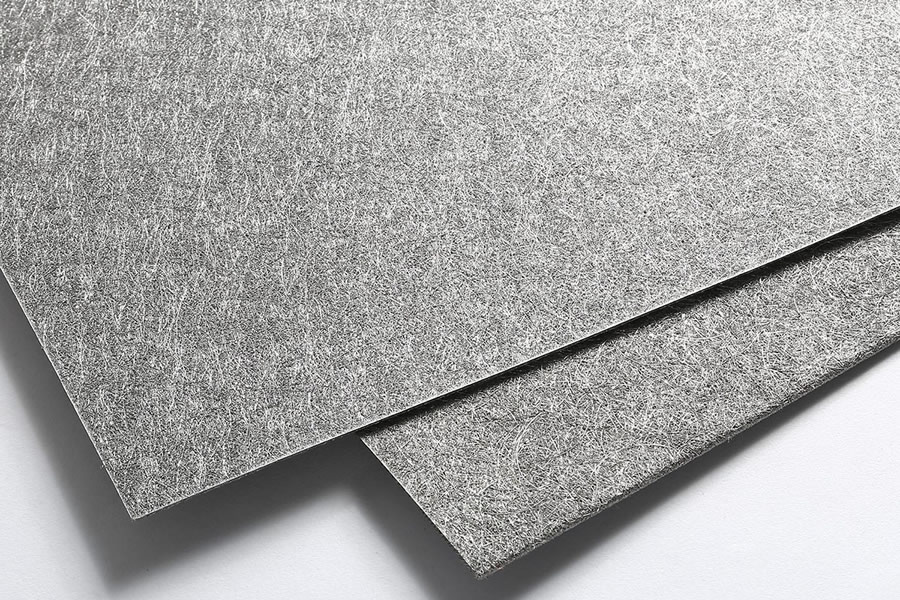

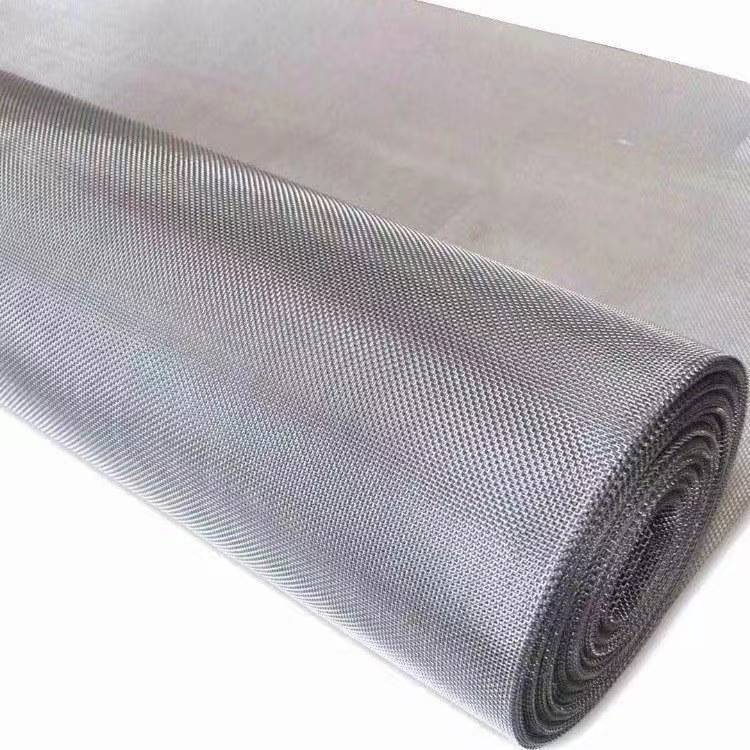

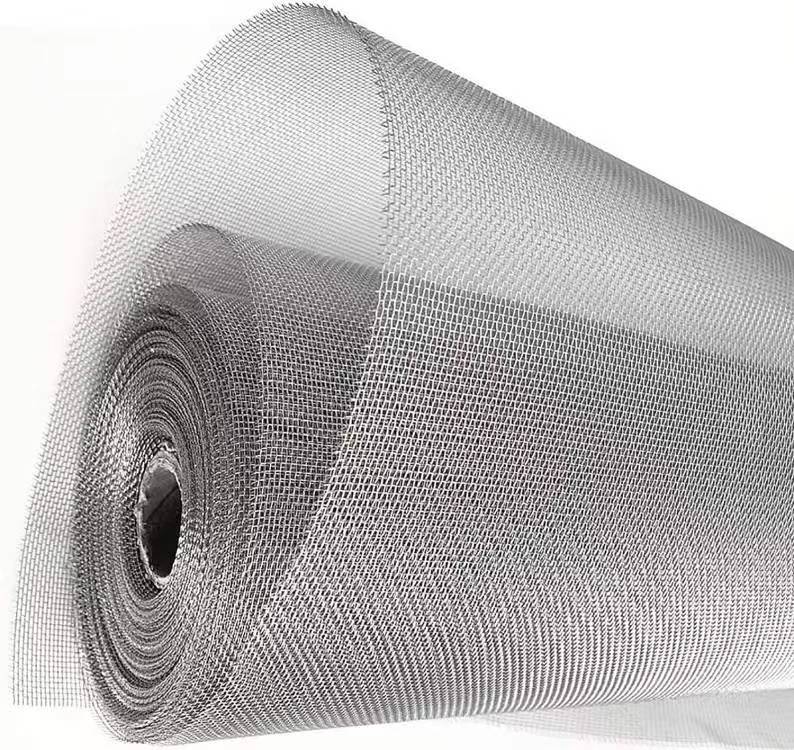

Product Photo Showcase and Alias

Sintered Metal Fiber Felt: Designed for robust filtration, this mat combines metal fibers in a sintered form, offering durability and efficiency in industrial filtering applications.

Metallic Fiber Felt: This felt is tailored for high-end filtration, leveraging the strength of metallic fibers to ensure optimal purity in various processing environments.

Sintered Fiber Metal Fabric: Ideal for demanding industrial uses, this fabric merges the flexibility of fibers with the resilience of metal, providing a unique solution for filtration and separation.

Metal Fiber Filtration Felt: Specifically crafted for filtration tasks, this felt excels in capturing impurities, combining metal fiber’s precision with felt’s trapping capabilities.

Porous Metal Fiber Mat: This mat features a porous structure, ideal for applications requiring breathable yet strong materials, particularly in filtration and aeration processes.

Sintered Metallic Fiber Media: Designed for high-performance filtering, this media utilizes sintered metallic fibers, offering superior durability and efficiency in fluid and air purification.

Metal Fiber Filter Felt: This felt is engineered for precision filtering, harnessing metal fibers’ strength to provide superior clarity in various liquid and gas filtration applications.

Fiber Metal Sintered Sheet: Combining the robustness of metal with the flexibility of fibers, this sheet is a go-to for industries needing strong yet adaptable filtration materials.

Metal Fiber Sintered Laminate: This laminate offers layered protection and filtration, ideal for complex industrial processes requiring both strength and fine particulate trapping.

Sintered Fiber Mesh Felt: Mesh-like in design, this felt is perfect for applications needing a blend of air flow and filtration, utilizing sintered fibers for enhanced performance.