JD Hardware Wire Mesh Co., Ltd specializes in producing Sintered Hastelloy Filter products, using the distinguished Hastelloy C series. This series features a nickel-molybdenum-chromium alloy with tungsten, providing outstanding corrosion resistance in various challenging environments. Our filters effectively withstand exposure to substances like hypochlorite, wet chlorine gas, and chlorine dioxide solutions.

Our Hastelloy C-276 (UNS N10276) offers excellent resistance to pitting and crevice corrosion, especially in harsh chemical environments with sulphuric, acetic, phosphoric, and nitric acids. It also resists grain-boundary carbide precipitation during welding, enhancing longevity and structural integrity.

We also provide Hastelloy C-22 (UNS N06022), which excels in high-temperature applications and has improved pitting resistance, making it suitable for demanding industrial applications.

The Hastelloy C range efficiently handles oxidizing chloride salt solutions, including those with iron and copper ions. These filters perform exceptionally in seawater, surpassing common alloys like 316L, 904L stainless steel, Monel 400, and Inconel 625, especially under crevice corrosion conditions.

JD Hardware Wire Mesh Co., Ltd’s commitment to quality and innovation ensures that our Sintered Hastelloy Filter products are not only reliable but also a superior choice for a wide range of industrial applications.

The Ingredient List for Hastelloy C276 and C22

- Hastelloy C276 (EN 2.4819):

Ni: Balance

Fe: 4-7%

Cr: 14.5-16.5%

C: 0.01% max

Mo: 15-17%

Other: W (3-4.5%), Co (2.5% max), Mn (1% max), V (0.35% max), Si (0.08% max), P (0.04% max), S (0.03% max) - Hastelloy C22 (EN 2.4602):

Ni: Balance

Fe: 2-6%

Cr: 20-22.5%

C: 0.010% max

Mo: 12.5-14.5%

Other: W (2.5-3.5%), Co (2.5% max), Mn (0.5% max), V (0.35% max), Si (0.08% max), P (0.02% max), S (0.02% max)

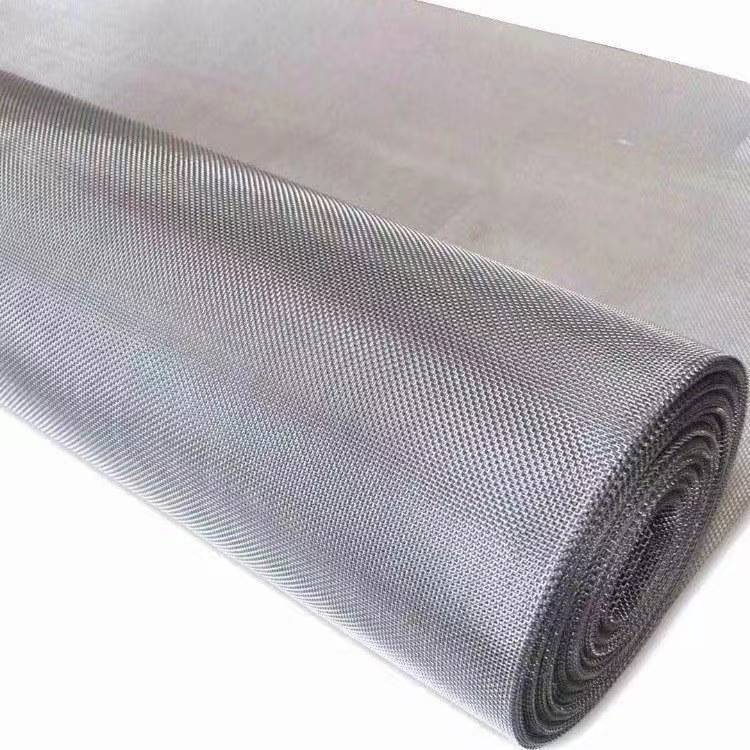

Hastelloy C276 and C22 Sintered Wire Mesh: Specifications and Dimensions

- Micron Ratings: The Hastelloy C276 and C22 sintered wire mesh are designed with a versatile micron rating, ranging from 5 to 200 microns. This broad spectrum allows for a variety of filtration applications, accommodating different levels of filtration needs.

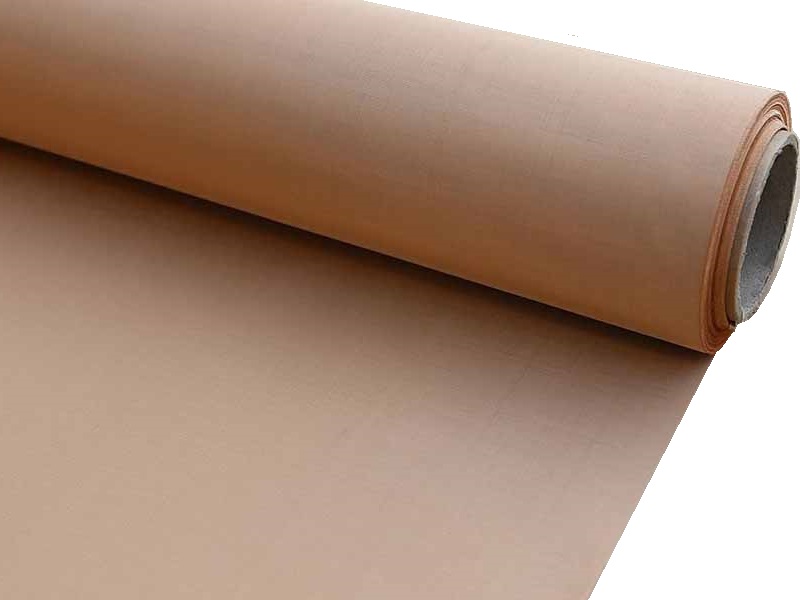

- Composition and Structure: These meshes are composed of high-quality Hastelloy materials, ensuring durability and resistance to corrosion. The unique composition of Hastelloy, incorporating elements like nickel, molybdenum, and chromium, provides superior performance in challenging environments.

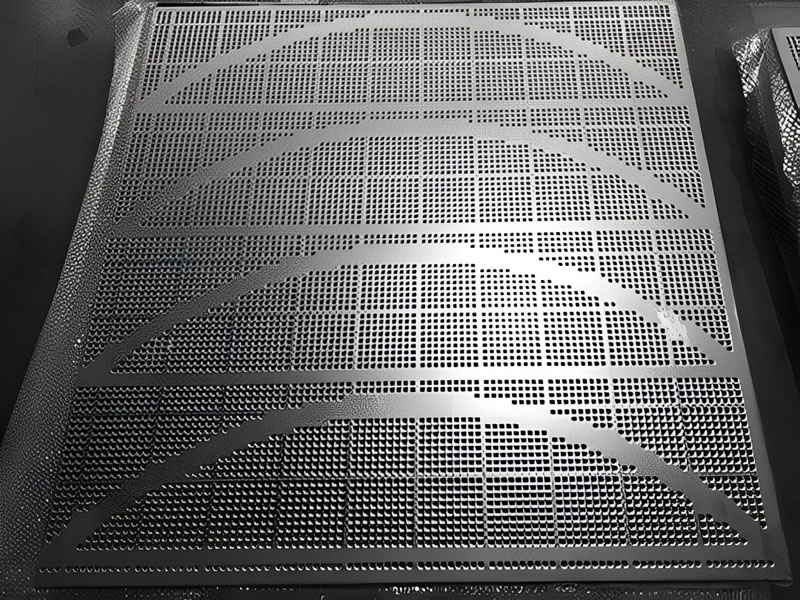

- Perforated Metal Integration: In addition to the standard sintered wire mesh, there is an option for Hastelloy perforated metal. This addition enhances the structural integrity and versatility of the mesh. The combination of sintered wire mesh with perforated metal offers a robust solution, entirely made from Hastelloy materials, for more demanding applications.

- Customizable Solutions: Given the diverse application areas of these meshes, customization in terms of dimensions and specific design requirements can be accommodated to suit various industrial needs. Whether it’s for intricate filtration systems or heavy-duty industrial use, the Hastelloy C276 and C22 sintered wire mesh can be tailored to meet the exact specifications of the project.

Applications

- Chemical Processing: In the chemical industry, these filters are essential for handling corrosive materials and ensuring the purity and safety of chemical processes.

- Pharmaceutical Production: In pharmaceutical manufacturing, Hastelloy filters play a crucial role in maintaining sterility and preventing contamination during the production process.

- Pulp & Paper Bleaching: These filters are used in the pulp and paper industry, particularly in the bleaching process, to ensure the removal of impurities and the maintenance of product quality.

- Oil & Gas Production: In the oil and gas sector, Hastelloy filters are employed for their durability and resistance to harsh conditions, aiding in the efficient and safe processing of oil and gas products.

- Petrochemical Process: These filters are instrumental in petrochemical plants, where they assist in various stages of petrochemical processing, handling a range of chemicals and temperatures.

- Fuel Gas Desulfurization: Hastelloy filters are used in the desulfurization of fuel gases, an essential process for reducing harmful emissions and environmental impact.

- Seawater-Related Filtration: Their excellent corrosion resistance makes them ideal for filtration applications involving seawater, especially in processes where other materials might fail due to saltwater corrosion.

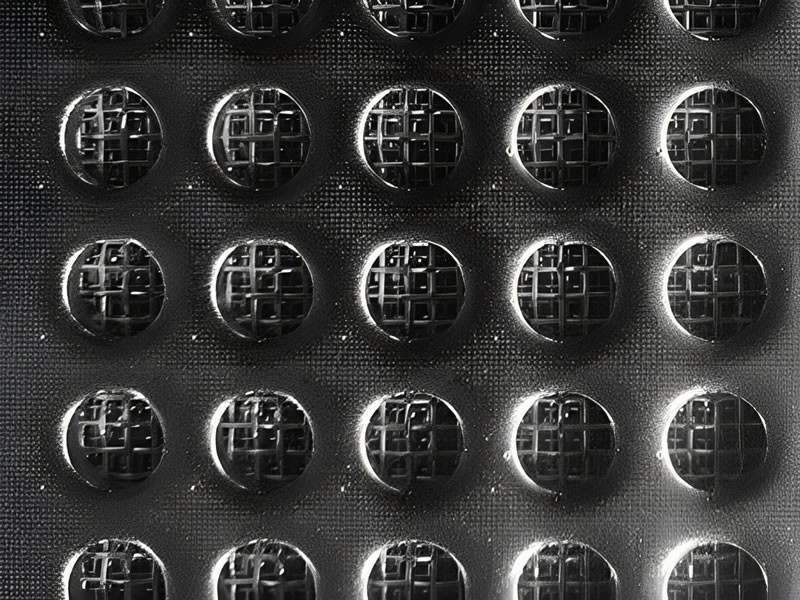

Product Photo Showcase and Alias

Sintered Hastelloy Chemical Filter: Primarily used in chemical processing, this filter excels in handling aggressive substances and maintaining purity in various chemical reactions and processes.

Sintered Hastelloy Pharmaceutical Filter: Designed for the pharmaceutical industry, it ensures contamination-free production and maintains the high sterility required in drug manufacturing.

Sintered Hastelloy Pulp & Paper Filter: Utilized in the pulp and paper industry, particularly in bleaching processes, it is essential for removing impurities and maintaining the quality of paper products.

Sintered Hastelloy Oil & Gas Filter: In the oil and gas sector, this filter stands up to the rigorous demands of processing, offering durability and reliability in harsh production environments.

Sintered Hastelloy Petrochemical Filter: This variant is tailored for the petrochemical industry, handling a variety of chemicals and temperatures efficiently during different stages of processing.

Sintered Hastelloy Gas Desulfurization Filter: Used in reducing harmful emissions in fuel gas desulfurization processes, it plays a crucial role in environmental protection and emission control.

Sintered Hastelloy Seawater Filter: Ideal for filtration involving seawater, it resists saltwater corrosion, making it perfect for marine and coastal industrial applications.

Sintered Hastelloy Industrial Filter: A general-purpose filter for various industrial applications, it offers versatility and high performance in diverse manufacturing and processing environments.

Sintered Hastelloy Environmental Filter: This filter is geared towards environmental protection applications, effectively removing contaminants and pollutants in various eco-friendly processes.

Sintered Hastelloy High-Temperature Filter: Specially designed to operate in high-temperature environments, it maintains integrity and performance in industries where heat resistance is paramount.