JD Hardware Wire Mesh Co., Ltd. stands at the forefront of providing tailored services for wire mesh applications across a variety of industries. Our offerings encompass a broad spectrum of processes such as Slitting, Cutting, Shearing, and Degreasing, all designed to ensure that your wire cloth and mesh are primed for immediate integration into your production workflows.

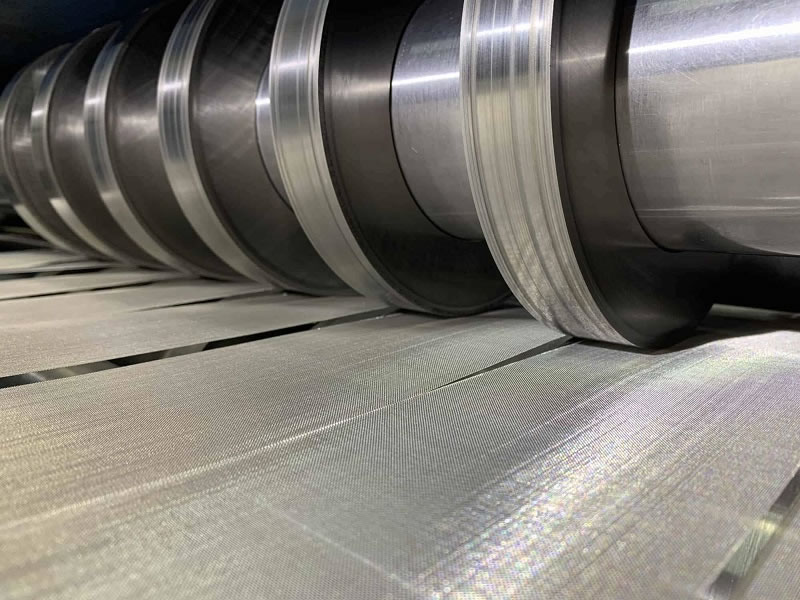

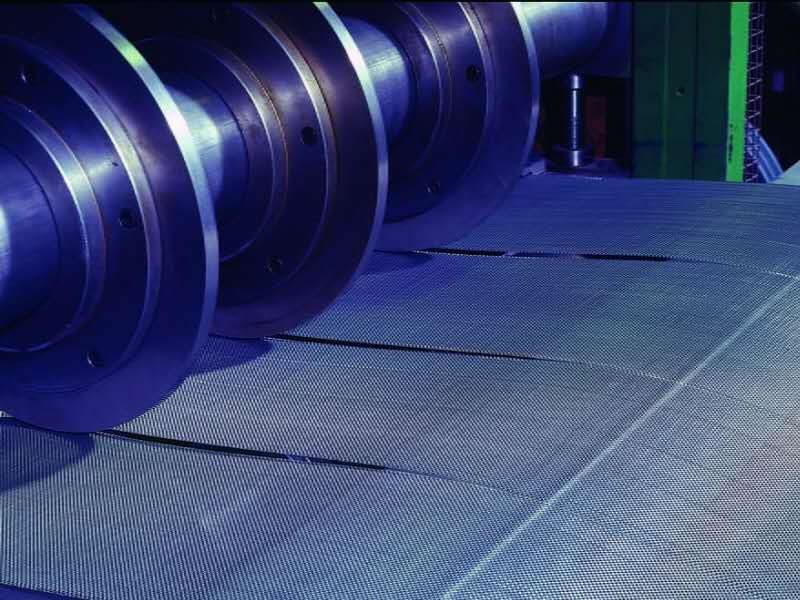

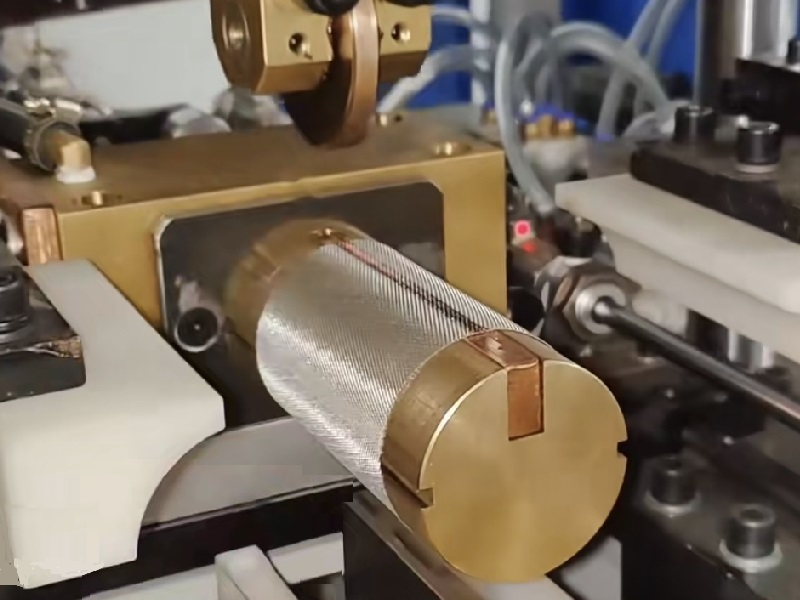

Slitting Services

- We cater to the specific needs of clients requiring wire mesh prepared for production, especially for filter elements or stamping operations. Our slitting services produce coils from widths of 10mm upwards, maintaining a standard tolerance of +/- 0.5mm. For projects demanding greater precision, tighter tolerances are achievable dependent on the mesh specification. Available core sizes are 50mm and 75mm IDs, with options for coils to be provided with or without cardboard cores. Depending on mesh type, coil lengths can reach up to 50m, accommodating various project scales.

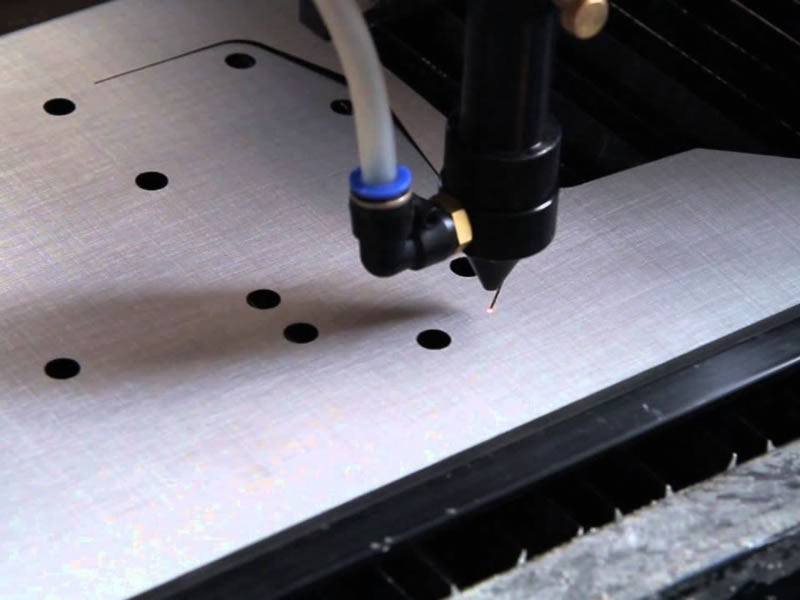

Cutting & Shearing Services

- To streamline production and minimize pre-processing costs, we supply wire cloth and welded mesh cut to specific dimensions. Our advanced shearing lines are adept at meeting any size requirement with stringent tolerances, ensuring materials are delivered promptly to maintain your production timeline. This commitment to precision and efficiency guarantees that the materials seamlessly fit into your manufacturing processes, ready for immediate use.

Cleaning & Degreasing Services

- Ensuring the cleanliness of wire cloth and welded mesh is paramount, which is why our ultrasonic cleaning and degreasing services are essential for removing all forms of contaminants. Regardless of the form in which the materials are supplied (rolls, coils, or cut parts), our cleaning process ensures they are free from dirt and oil. We take extra precautions in packaging to avoid any contamination during transport and storage, ensuring that the materials remain in pristine condition for production.

JD Hardware Wire Mesh Co., Ltd. is committed to delivering not just products but comprehensive solutions that enhance the operational efficiency and product quality of our clients. Our specialized services are designed to provide ready-to-use materials that meet the exact requirements of diverse manufacturing environments.