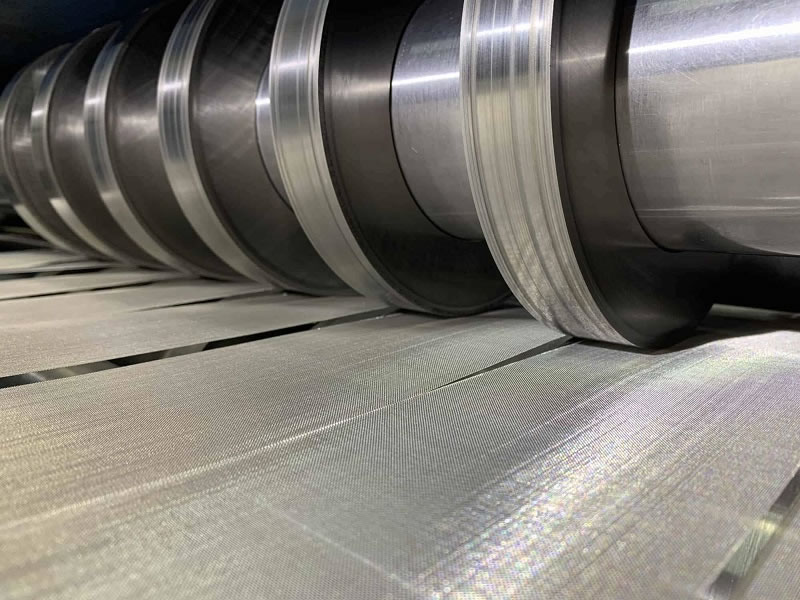

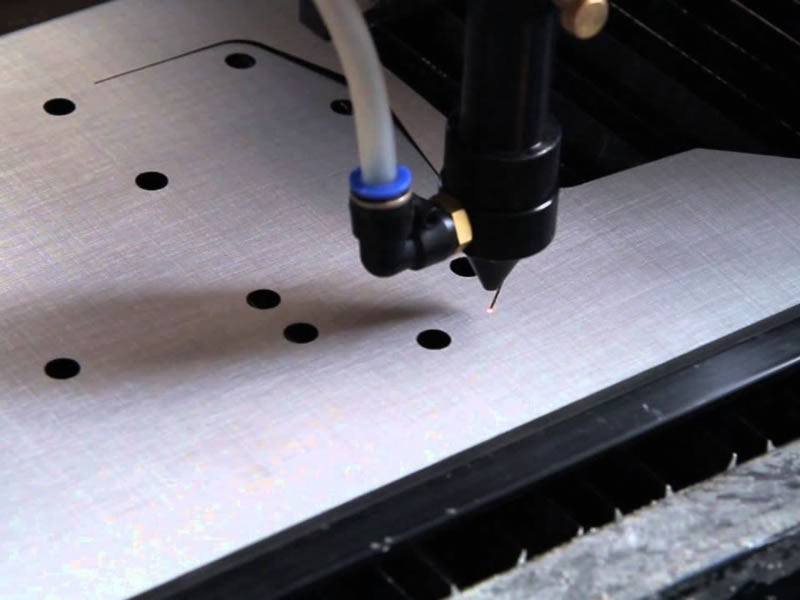

JD Hardware Wire Mesh Co., Ltd. specializes in advanced Pressing & Forming services, employing cutting-edge technology and equipment to meet the diverse needs of our clients. Our capabilities extend to utilizing CNC machines for precise shearing, notching, and punching of angles and flat bars, enabling us to craft metal components with unparalleled accuracy and efficiency.

Pressing & Forming Services

Our facility is equipped with the latest sheet and plate machines featuring computer numerical controls (CNC) for enhanced production repeatability. Programmed directly from CAD software, our machinery minimizes errors and optimizes the manufacturing process. We excel in working with material thicknesses of ½ inch and below, ensuring precise outcomes for a wide range of project requirements.

In addition to our cutting-edge punching techniques, we offer comprehensive CNC metal forming and bending services. Whether the project calls for simple 90° bends or more complex sequences involving multiple bends, our press brakes are capable of shaping both small and large parts to exact specifications. Our commitment to utilizing advanced technology, combined with the skill of our team and stringent process controls, ensures the highest level of formability and repeatability to satisfy customer demands.

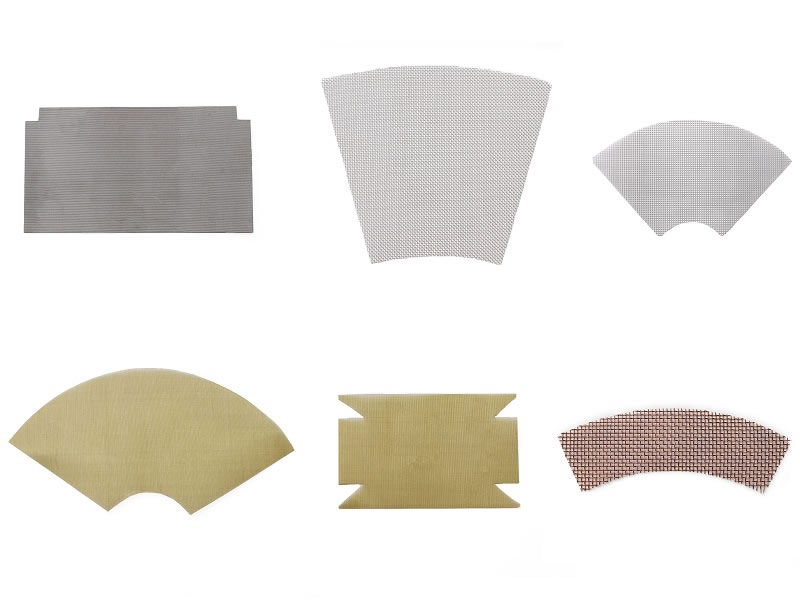

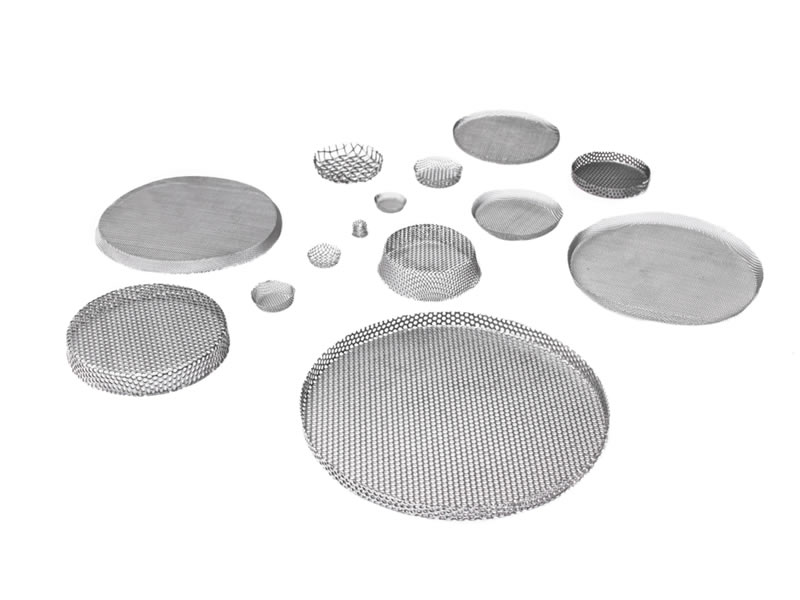

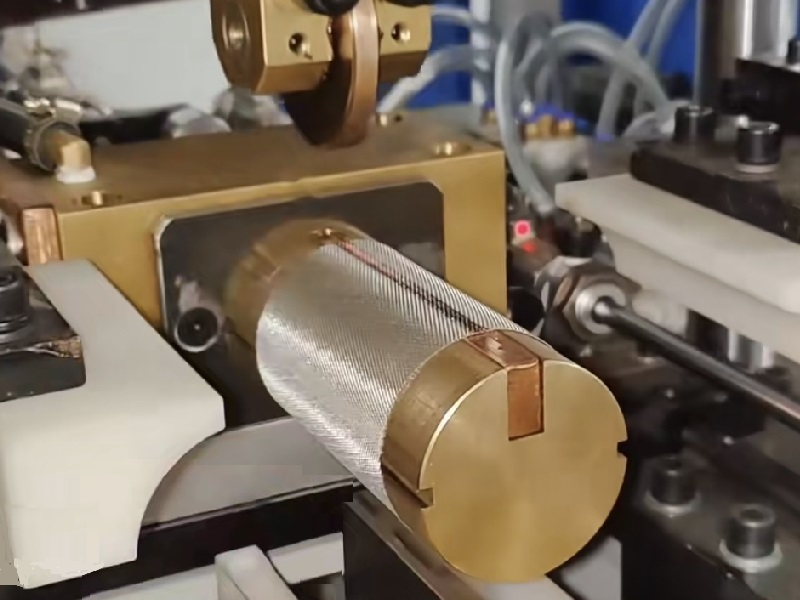

Shaped & Punched Wire Mesh Solutions

JD Hardware is dedicated to providing custom shapes and configurations to meet the specific specifications and requirements of our clients. Our services include economical stamped parts available in a myriad of configurations, alongside laser cut or plasma cut parts ideal for prototypes and small-run parts. With a comprehensive selection of standard round dies for stampings, we are equipped to handle a variety of projects. Furthermore, for those in the early stages of design or in need of additional information regarding our cutting or stamping capabilities, our team is ready to offer expert guidance and support.

JD Hardware Wire Mesh Co., Ltd. is your trusted source for high-quality pressing and forming services. Our dedication to precision, efficiency, and customer satisfaction ensures that we deliver superior components and fabricated parts for subassemblies, tailored to the unique needs of each project.